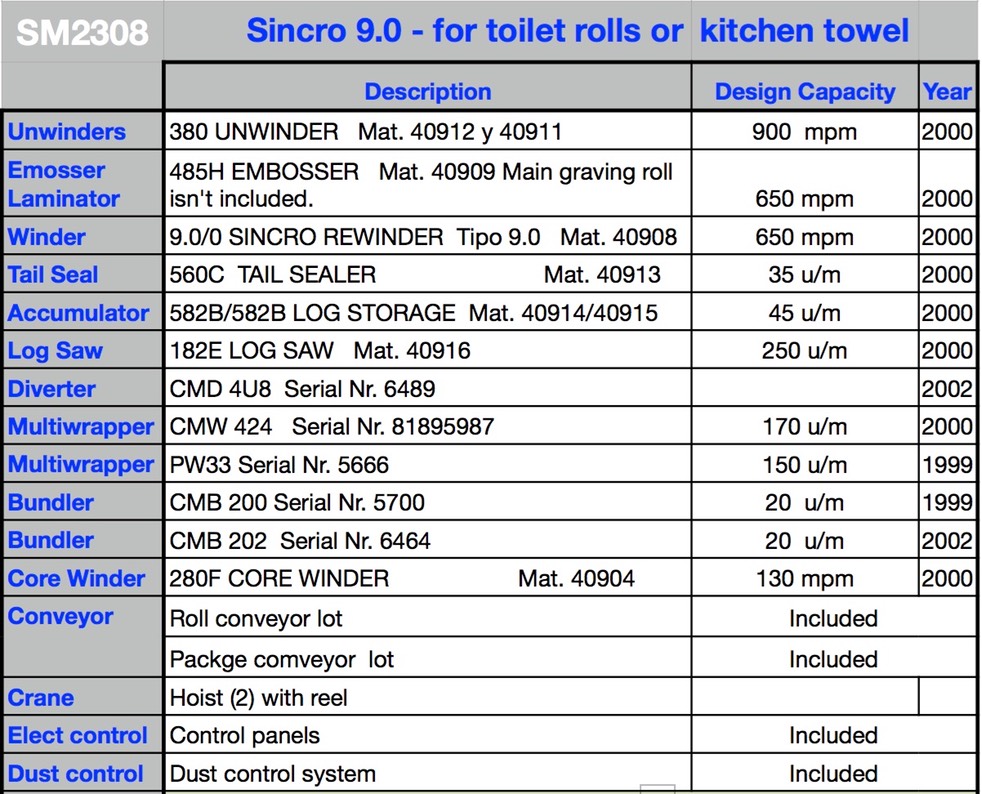

UNWINDER: Perini 380

Fully automatic system with loading and unloading of the parent reels

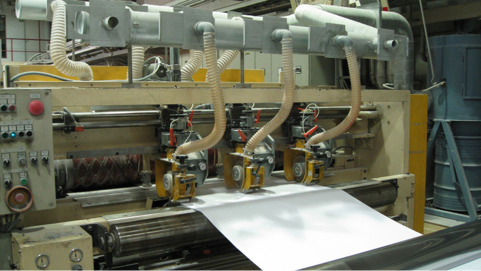

EMBOSSER:

Perini 485H(Main embossing pattern roll isn't included.

A modular, versatile and easy to operate rubber/steel embosser for toilet roll or

kitchen towel converting lines. Reaching a maximum speed of 700 mpm, it

makes various kinds of single or double-ply products. The amount of bulkiness

and softness in the end product can be varied by combining different embossing

patterns in the web.

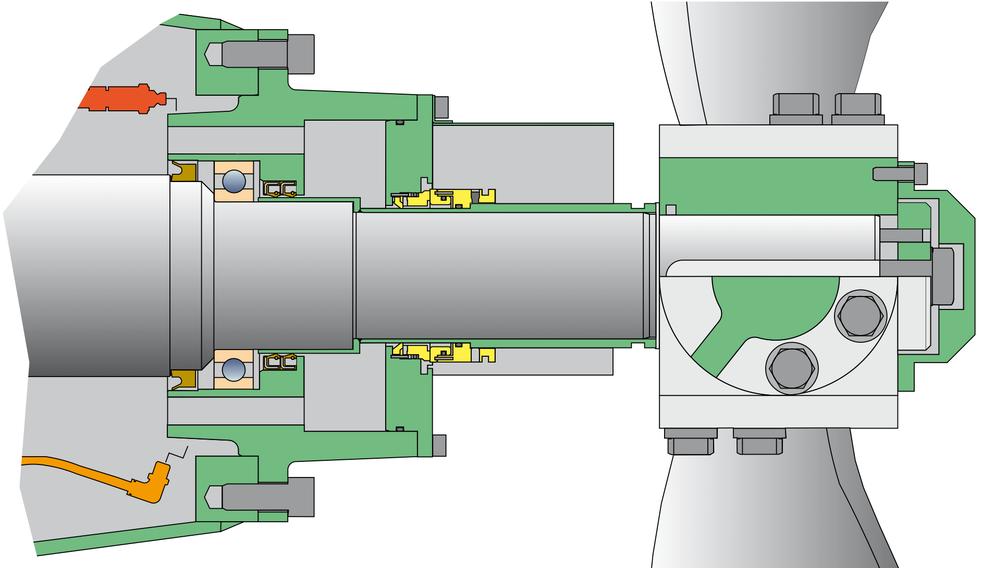

REWINDER:

Perini 9.0/0 SINCRO

SINCRO System

Since the introduction of our revolutionary three-roll winding system more than 30 years ago, it has proven its ability to deliver absolute transfer precision at maximum speed even today. In this surface system, the log is freely wound on the cores, with no need for a mandrel. Even the transfer system is optimized; the transfer is positive and does not involve the vacuum roll or cutting blade. Thread-up is accomplished by the rotating Sincro roll bringing the web close to the core. The winding rolls stay clean because the core, once glued, is immediately wrapped by the web.

Tail Sealer:

Perini 560CVL

True to our goal of giving you increased efficiency and ease of use, the tail sealer model 560CVL works up to 45 logs/min, at diameters of up to 160 mm. A doctor blade system assures the quality of the final tail seal by metering exactly the right amount of glue on the web. Its simple and rational mechanics contribute to drastically reduced maintenance costs.

Accumulator:

Perini (Two of) 582B & 582B

The core accumulator’s working principle is based on the well-known FIFO (First In - First Out) where cores are channeled inside a forced path, without ever being crushed, deformed or solicited, all employing the same amount of time for transit before entering the winding area of the rewinder at a speed of up to 80 cores per minute.

LOG SAW: 182E

This new model is the fastest, most versatile and modern log saw on the market today. It optimizes cutting quality on soft, bulky products (TAD), for increased production. Its two rotary-oscillating blades attain a speed up to 300 strokes/minute and are fully panel-controlled. Log diameter is also changed directly from panel, covering a range from 90 mm to 152.4 mm, with universal clamps for great flexibility.

Trims System: Included.

Diverter:

CMD 4U8

Ideal for use in tight spaces and where line flexibility is key, a wide range of solutions are available to meet virtually any production need.

Multi Wrapper

1) CMW 424

This high speed wrapper combines versatility, flexibility and reliability. Handles rolls with diameter up to 200 mm. and with the application of servomotors on a few components, all the movements drive independently making the machine easy to operate and above all granting a high quality finished product.

The use of energy saving drives of latest generation will substantially reduce

consumptions and protect the environment.

2) PW33

Bundler

1) CMB 200

2) CMB 202

This high speed tissue bundler combines high production speed (up to 20 bundles/minute) and reliability. It’s easy to use and highly flexible, being able to bundle packs with horizontal and/or up-ended rolls, as well as single rolls, while maintaining the highest product quality.

Core Winder:

280F CORE WINDER

An automatic unit with vertical former and fixed mandrel that produces

cores up to 5,500 mm in length, at a speed of up to 165 m/min.

Attention to technical detail makes it an extremely flexible machine. Core

characteristics can be set easily, the diameter changed quickly and

easily, the thickness chosen up to 1.5 mm.

Cores can be produced using from one (with the optional LITEPly® System), up to three strips. Each working phase of the core winder is

electronically adjustable to assure that operations among the various components – from core production up to cutting and core discharge – are synchronised at all speeds, without having to stop the machine. This results in perpendicular cuts every time.

Conveyors

Roll conveyor lot

Packge conveyor lot

Hoist:

Control Panels: Included

Dust Control System: Included

Hoist with reel

(2)