PULP MILL, SEMI -CHEMICAL Sulphite, 18,5 BDT/H (430TPD)

MACHINERY LIST

- Wood park

- Chemical products

- Pulp mill

- Evaporation

- Stripping warehouse

Wood park

- Manufacturer: RAUMA REPPOLA

- For the preparation and stockage of chips

- Chipping capacity: 1.120 tpd

- Stockage capacity: max. 55.000 Tn.

- Transportation equipment for continuous feeding of logs:

- 1 Belt conveyor for receiving the logs

- Max. capacity: 150 Tn/hour

- Width: 3.200

- Length: 8.100

- Height: 5.100

- 2 Chain conveyors for waste

- Rolls conveyor for logs

- 900 m. width x 5.500 mm. length

- 15 Dented rolls

- Logs cleaning by cold recycled water and some clean water

- 2 Purges for stones

- 1 Transport belt for feeding the chipper

- Width: 1.200 with metal detector

- 1 Fixed crane for maintenance with remote control JONSERED J 1820 type, year 2.004

- 1 Chipper and enclosed material

- 1 RAUMA REPPOLA chipper 12.3000 type

- Length of cut: 21 mm.

- Disc of 3.000 mm. with 12 knives, 300 rpm

- VOITH Hydraulic couplings

- 2 Motors of 5.500 V, 500 Kw each one

- Speed: 1.475 rpm

- Set of knives

- 1 Blowing cyclone for chips

- 1 Set of classification and sortage

- 1 Clasifier capacity 600 m3/h 5.000 m. x 4.000 m, holes of 50-18 – 4 by SUND DEFIBRATOR

- 1 Conveyor belt (by chain)

- 1 SUND DEFIBRATOR rechipper 81.220 type, overhauled in August 1.995

- 8 Knives

- 1 Screw

- 1 RADER Feeder

- 1 RADER Surpresser

- 1 RADER Tank for stockage

- Installation for collecting the chips

- 2 Belt conveyors

- 1 RADER Feeder and 1 RADER Surppreser

- 1 Magnetic separator

- Earth treatment

- 1 Chain conveyor

- 3 Band conveyors

- 1 Sieve

- 1 Hammer mill

- Miscellaneous little tools

- 1 Granulometric control for cuts CHP CLASS type

Chemical products

- Manufacturer: CELLECO (Sweden)

- Process: Liquor of monosulfite of ammonium from sulphur and ammoniac

- SO 3 (NH42) 205g/l PH 7.4

Material:

Sulphur circuit:

- 3 Tanks of 30 Tn. Total 90 Tn.

- 1 Sulphur kiln of 15 tpd pulverised by comprised air or steam. Length: 15 m. x diam. 0,80 m.

- 1 Cooling tower (inox 904 L). Height: 5,50 m. x diam. 0,90 m.

- 1 Suction tower. Height: 12 m. x diam. 0,80 m. Height: 12 m. x diam. 1,80 m. Intalox equip.

Liquid NH3 tank:

- 1 Exchanger

- 1 Mixer

- 1 Buffer tank

Set of 17 pumps

Pulp mill

Digester:

- capacity 55,9 m3, length 16,8 m. x diam. 2,10

- Carrying of chips by belts with variable speed

- Manufacturer: VOEST-AUSTRIA, BAUER license

- Production: 420 tpd

- Raw material: chips of 12 to 24 mm. 10 % chemical products

- Performance: 80 % dry/dry in digester

- Reactive: Solution of monosulphite ammonium at 205 gl SO 3 (NH 42)

- Consumption: wood 910 tpd brut, sulphur 15 tpd, ammoniac 15 tpd

- Cooking time: 20 min. at 175º, 9 bar

- Shopper degrees: defibrating entry 14º SR, refining entry 48º SR

- Cleaning efficacy: index in treated water less than 10, in clear water less than 45

- Pneumatic transportation: RADER can admit 800 tpd of wood

- Chip cleaning: capacity 220 m3/h. Average: 52 %

- Presteamer: of 12 m3. Height 8,50 x diam. 1,60

- Heater: of white liquor with:

- 1 ASET horizontal tubular exchanger, BEU 273-2600 type

- 2 ASET horizontal tubular exchangers, BEU 273-2700 type

- 1 ASET vertical exchanger, BEM 508-6000 type

- - 2 Rotary valves of 18 inches at entry and exit of boiler

- - 1 Live bottom tank of 20 m3 with calory recovery, width 2,1 x height 4

- - 4 FMW Screws to transport the pulp. Diam.: 500 mm.

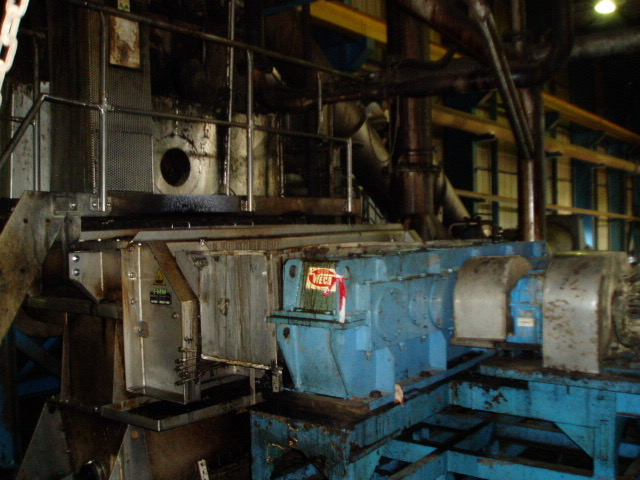

- - 2 SUND Defibrators, 412 F type, 40” each one with 2 motors of 920 Kw, 1.500 rpm, 5.500 V double disc.

- With hydraulic oil pressure system to assure the adjustment.

- Dryness: around 38 % at entry. 20/25 % at exit.

- 3 RAUMA REPPOLA Filters for pulp cleaning under pressure and working against current, three stages, power: 25 Kw. Motor speed: 300-1.450 rpm. Surface: 82 m2 each one.

- The first and second filters are fed by the middle vat, the pulp of the third filter falls into a screw conveyor. Each filter has a fan for vacuum.

- Steam condensator 12 Tn/h. surface 430 m2 pressure, outside tube 4 bar

- Exit filter nº 2

- 1 SUND Pump for thick pulp

- Pulp concentration: 18 %

- Power: 75 Kw, 2 bar, 120 m3/h.

- Malone filter diam. 800 x 1.000

- Exit filter nº 3

- 1 MCEM SULZER Pump

- Pulp concentration 12 %

- Power: 160 Kw

- Production: 18,5 BDT/H semi-chemical pulp

- Set of 51 pumps

- 1 FOXBORO Control system

- To control all the cooking

Refining

- 3 SPROUT WALDRON Refiners 42”, 1.500 Kw

- 4 ALLIMAND Refiners 36”, 750 Kw

Evaporation

- Primary evaporation:

- Manufacturer: APV

- Type: mechanical recompressure

- Capacity: 32 Tn/h.

- Steam consumption: 0 Tn.

- Absorbed power: 700 Kw/h.

- Consistency at entry: 10 %

- Consistency at exit: 25 %

- 1 AHLSTROM RATEAU Overcompressor

- 2 ROSCO Evaporators

- Set of pumps

Secondary evaporation:

- Manufacturer: ESCHER-WYSS

- Evaporation capacity: 39 T/h. black liquor at 10 %

- Steam consumption: 13 T/h. low pressure

- 400 Kg. of dry materia per pulp tonne at 10 %

- 2,7 Tn. of evaporated water / Tn. of steam at low pressure

- Consistency at exit: 60 %

- Consists of three counter-current effects:

- Nº 1 of 340 m2 and 520 tubes

- Nº 2 of 310 m2 and 276 tubes

- Nº 3 of 310 m2 and 276 tubes

- 1 Condensator of 220 m2 and 544 tubes making between 350 and 450 m3/h of water at 40ºC

- 1 Heater of 40 m2 and 56 tubes

- 3 Vacuum pumps

- Set of pumps

Stripping plant

- HERMEX Lime tank, year 1.995:

- Volume 100 m3, diam. 4.200, height 10.200, mechanical filter, 12 m2

- SODIMATE Lime dossifier, year 1.995:

- DDMR 120 SC Type

- L2M Stock preparation of lime milk, year 1.995:

- 1 m3, diam. 1.300, height 1.150, with Mixel MM500 agitator

- L2M Stockage of lime milk, year 1.995:

- 11 m3, diam. 2.500, height 2.100, with Mixel MM900TF600 agitator

- 2 Air compressors, year 1.995:

- Capacity 27,18 m3/min. Pressure differential 0.5 bar, Installed power 37 Kw, 2.920 rpm.

- 2 MLABBE Reactors, year 1.995:

- Diam. 3.800, height 7.500, capacity 45 m3, shaken volume 23 m3, ROBIN agitator, type F5 140 37/21, installed power 37 Kw

- M LABBE absortion tower, year 1.995:

- Diam. 1.000, height 13.000, 3 suction plates, internal pressure 0,5 bar, Tº 100ºC, ABB FOUGAL HK Fan

- M LABBE Condensator, year 1.995:

- Diam. 1.150, height 7.800, P= 3 bar, 262 tubes of 51 mm. diam. x 1 m. Vacuum inside the tubes of 7 m. water column

- Aircooler, year 1.995:

- Capacity 160 m3/h, RPA 3029-5352006185B Type

- Plates heat exchanger, year 1.995:

- Capacity 10,92 m2 + 5,88 m2, DN 100, structure of stainless steel

- Cooling system, year 1.995:

- SCX 276 R.00, power 350.000 fg/h, 570 W, water capacity: 100 m3/h.