From Waste To Wealth

Recycling of the polymers and foils from Liquid Packaging

(Please also see "PHOENIX FIBRE")

Phoenix plain Sheet

Phoenix corrugated sheet

Recovered Tetrapak raw material

Phoenix Sheet Manufacturing process

Feeding

Shredding

Preparation

Heating & Pressing

Advantages of Phoenix Sheet

- Unbreakable.- This unique property of the product gives longer life to the application. T.T.D. testing has proved the roof sheets to have high strength characteristics – even when run over by heavy vehicles!

- Easy to Install - the light weight of the sheets make it convenient and easy to handle and install.

- Low Water Absorption- because of the composition of the product together with its manufacture process, it has low water absorption.

- No Painting Required - As it has own green matt finish. The product can be coloured to tailored needs if required per product.

- Low Heat Absorption - Phoenix sheets are well suited for the secondary property of their raised thermal insulation in structures which located in areas of climate temperature extremes,

Galvanised Iron roofing

Phoenix corrugated roofing

- Replacement of Plywood MDF and Chip board - As a wood replacement product, RGS conserves natural resources while reducing waste pollution.

- No fungal Growth – The process used acts as a biocide eliminating fungal growth and reducing bacterial degradation to practically zero.

- Low weight per unit.

- Construction cost savings.

Application & Utilization of Phoenix Sheet

- Roof Sheet

- Side Cladding Sheet.

- Partition Wall from Plain Sheet.

- Interior Walls.

- Flooring with Plain sheet.

- False Ceiling From Plain Sheet.

- For Pallets.

- For Packing Boxes.

- Furniture items.

- Decorative items.

- Site Temporary Offices.

- Limited only by imagination

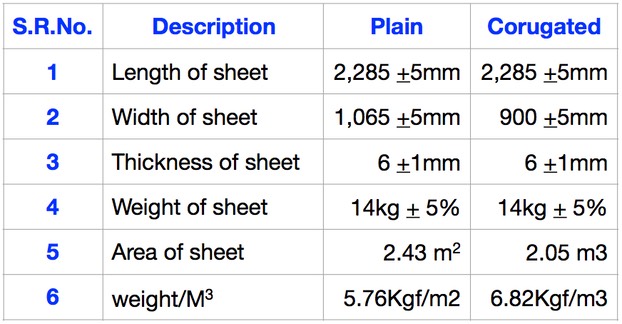

Specification of Phoenix Sheet

Automation

After building a research pilot plant to prove the process for technology and commercial viability, we have built the first automated stock preparation line for the process. This new automated line has undergone extensive trials as part of the ongoing research and development and the results is integrated in the first generation commercial plants being offered. These will incorporate PLC’s to suit either the 50hz or 60hz requirements of the end user.

Please Note: The following are photos from the initial research pilot plant and show the first manual processing stages and are just for illustration and historical information only.