“NO NONSENSE MACHINES AT NO NONSENSE PRICES”

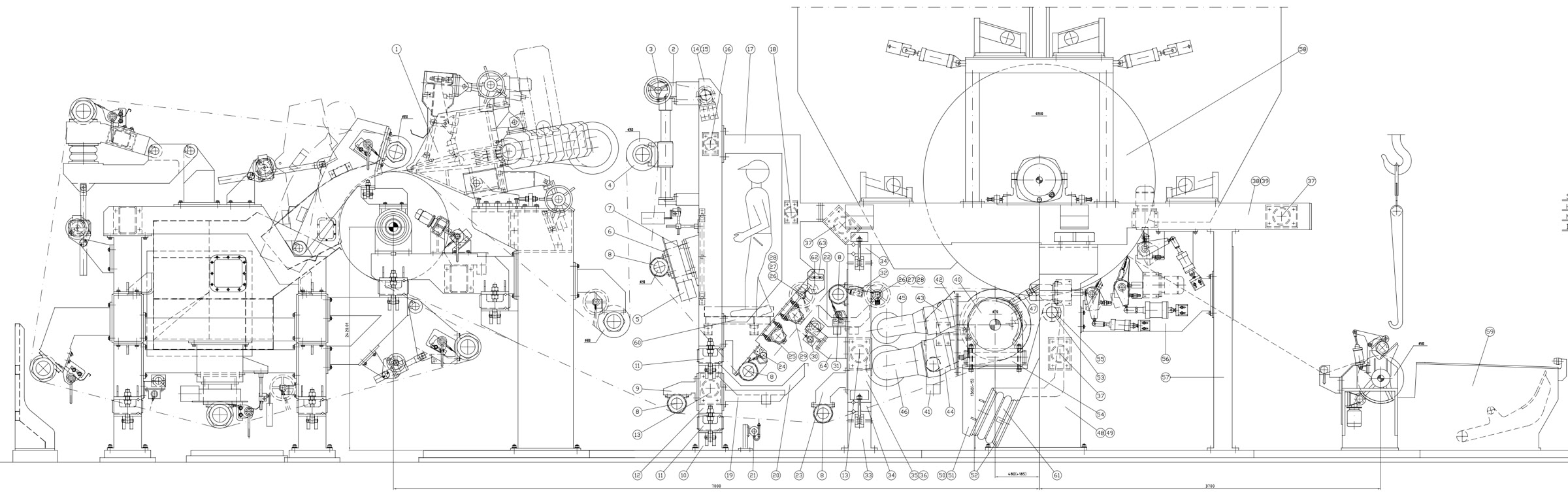

SM4045 - Tissue Machine Crescent Former – EXCLUSIVE SALES PARTNER

SPECIFICATION

Capacity 6,500 tons/annum (32 tpd)

Width 2,650 meters

Products manufactured Toilet (single & two ply)

- facial (white & colours) tissues,

- industrial & bathroom wipes,

- serviettes,

- linen saver

- kitchen towel

● RCF - Consumer A (20GSM)

● RCF – Consumer B (17.5GSM)

● Virgin – 2Ply (16.5GSM)

● Virgin – Facial white & colors (15GSM)

● Virgin – Facial interfold (15GSM)

● Virgin – Industrial wipe (17 & 35GSM)

BRIEF OVERVIEW

Tissue manufacturing plant

Manufacturer: Toschi Toscotec (Paper machine)

Voith for the majority of the stock preparation

Capacity : 32 tons/day

Raw Material: Recycled fibre (office waste) & virgin fibre (hard & soft wood)

Deckle: 26,50mm max,

Diameter : 1,450mm

Grammage: 14 to 35 GSM at 5.5% moisture.

COMPLIMENTED BY

Cast –iron Yankee of 2,500mm diameter,

Gas fired hood (300°C),

DAF unit to recycle waste water to process water at the rate of 30kl/hr

Voith De-inking unit

Two Pieralisi Jumbo-4 centrifuges to handle waste water at the rate of ±65C³/hr

TECHNOLOGY

- Plant process control - Honeywell - Total Plant Acont DCS R683

- Quality system – Honeywell – Experion MX

- DC drives ABB DCS 800 x 5 drives

UPGRADES:

- In 1994 - TOSCOTECH gravity cushion head box machine was installed at20t/day Product range – 1ply, 2-ply, Kitchen towel, Wipes & Facial tissues (15 to 35 gsm)

- In 1997 – rebuilt with Cresent former head box by TOSCOTEC along with stock prep upgrade with HD pulper, de-inking, screens, gas fired hood & Honeywell DCS.

- New control room – 1999

- New Quality Control System – 2000

- New process control system DCS – 2003

- Stock prep up-grade with deinking & screens – 2003

- Harmonics & Power factor panels upgrade – 2011-12

- DCS upgrade to replace tissue machine PLC – 2011-12

- Steam system upgrade – 2012-13

- Boiler burner upgrade – 2012-13

- Compressor replacement - 2013-14

- New QCS installation – 2016

COMPLETE REBUILD

- 2021 - After the mill site was closed and the machine relocated. This Included creating a standalone steel frame foundation on which the sole plates of the machine are set. The foundation frame utilises the pit of an older machine and is secured on the sole plates of the earlier machine (see below). When relocating this will facilitate a much simpler civil engineering project.