“NO NONSENSE MACHINES AT NO NONSENSE PRICES”

SM2446 - PCMC Toilet roll production line

COMPRISING:

1 x Unwind stand with max diameter 60”

1 x Embossing rolls section

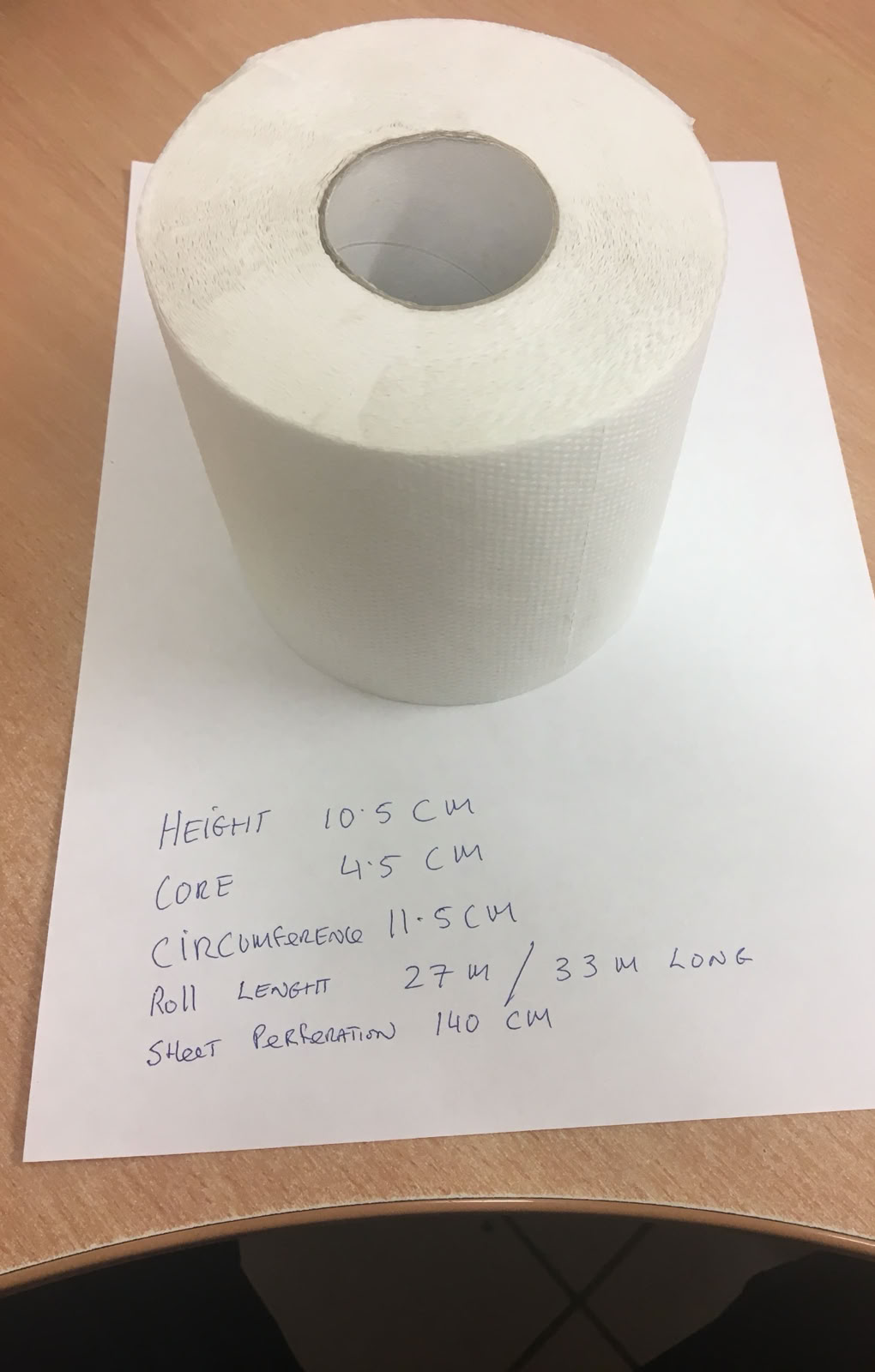

1 x PCMC rewinder, Model No 59087 complete with steel to steel embossing, 66” max web width, 44” Bedroll & 22” perf roll, with 5” perf - suitable toilet rolls or kitchen towel - Installed new mandrels, replaced sensors and fixed timing of machine. Installed new gears, new perforation blades with spares available (old mandrills available as well).

1x Core Hopper and Feeder - Repairs structure of the hopper.

1x Tail Seal Machine - New sensors and retimed machine.

1x Accumulator - Adjusted sensor timing to release logs at correct speed.

1 x PCMC logsaw Series 900, number R5413 (1992), with trimex and trims conveyor - New cutting gears to cut rolls to 100mm instead of 105mm so more production per log.

1 x Cassoli PAC 691 RT 3 lane Wrapper, Number 2749 (1991) - New control panel installed, new heat seal belts, Machine timing corrected.

1 x Wrapmatic BFA 25 Bundler, Number 50888120210792 (1992) - New motor for conveyors, timing fixed.

1 x One PCMC core winder series CM12, number 59955 (1992) and glue bath. - Machine completely repaired and programming carried out. New core mandrel and core winding belt and pully installed.

Complete with available motorised conveyors.