600 BDSTD Deink and Calendering Equipment

The former operation was based on using deinked reclaimed paper fiber, supplemental virgin chemical pulp and on-site mixed coatings to produce gloss and speciality grades of printing papers.

The grade mix was from lightweight coated (LWC) groundwood papers through medium weight coated (MWC) freesheet products, and included speciality label, inkjet and coated one-side (C1 S). These products were produced with pulps that varied from 8O% DIP and 20% market pulp, up to an 88 ISO brightness gloss MWC made from 100% DIP fiber furnish.

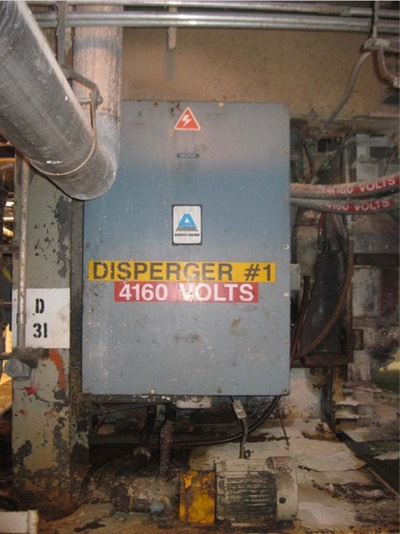

1) Best available DIP line based on drum pulping, two (2) Loop deink and dispersion systems, hydrogen

peroxide bleach system, coarse cleaning and screening system, fine cleaning and screening system,

sodium hydrosulfite bleaching plant and broke thickening;

2) Complete GAW 150 TPD coating mixing and storage plant;

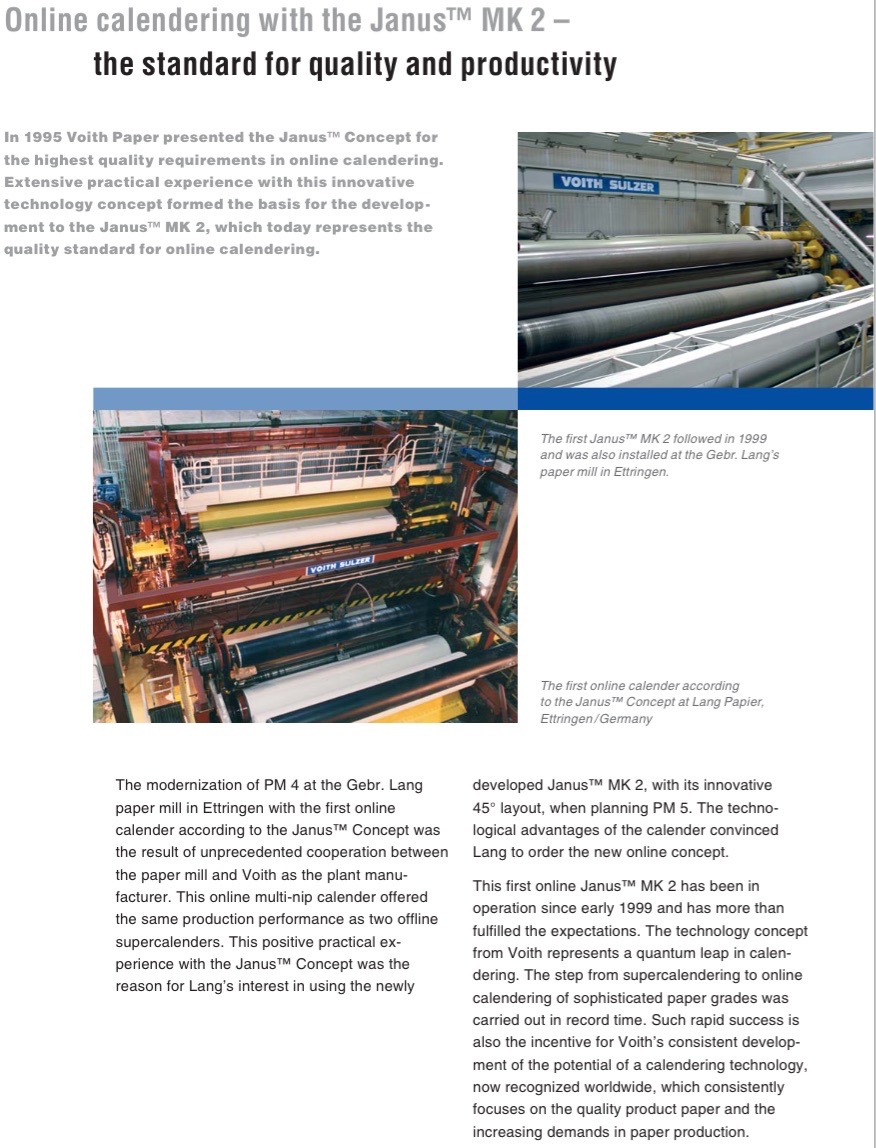

3) Complete Voith Janus On-Line hot/soft super calender system; and 4) Complete Metso roll wrapping line.

These are offered "as is, where is"; for timely removal. Complete with all available drawings, manufacturer's manuals and operator manuals.

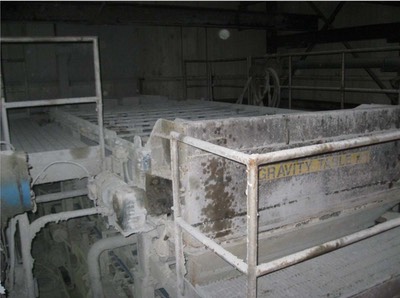

Deink Plant Equipment Available:

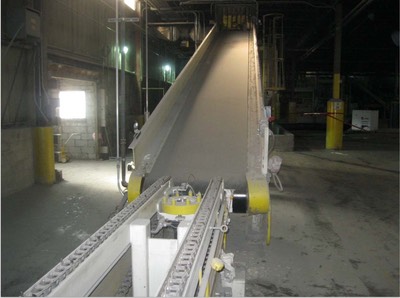

Calendering Equipment Available:

CRITERIA – DEINK PLANT