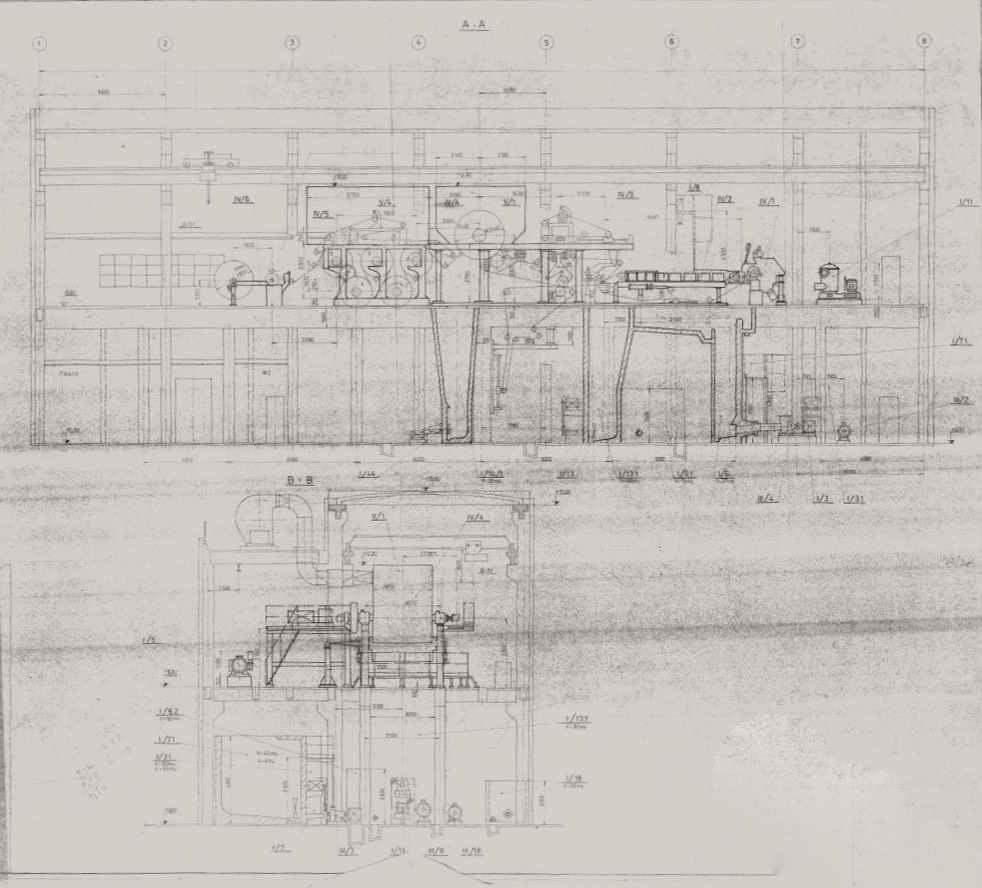

SM2026 - Tissue Machine Beloit Fampa, 2,700mm Toilet & Napkin, MG papers, 400m/min, 20tpd

TISSUE PAPER MACHINE

- Fabric width: 2.700 mm

- Paper width at the winder: 2.500 mm

- Maximum operating speed: 400 mpm

- Max. diameter of tambour reel 1800 mm

- Condition Good

GENERAL SPECIFICATION

- Machine supplier: BELOIT FAMPA - Polonia

- Year of manufacture: December 1986

- Stopped: September 2003

- Produced paper grades:Toilet crepes tissue - 30gsm,

- Tissue for napkins 25 g/m2, MG 25 – 90 g/m2

- Production capacity:18 - 20 tpd

- Production capacity: 6 000 tons per year (by 330 working days)

- Operating speed: Max. 400 m/min

Width of wire: 2,700 mm

Width of wire: 2,700 mm- Paper trimmed width: 2,500 mm

Max.diam. of tambour: 1,800 mm

Max.diam. of tambour: 1,800 mm- Used furnish: Virgin pulp

- Possibility of furnish: All mixture of virgin pulp and waste paper

- N.B. Waste paper stock preparation is not included in the offer

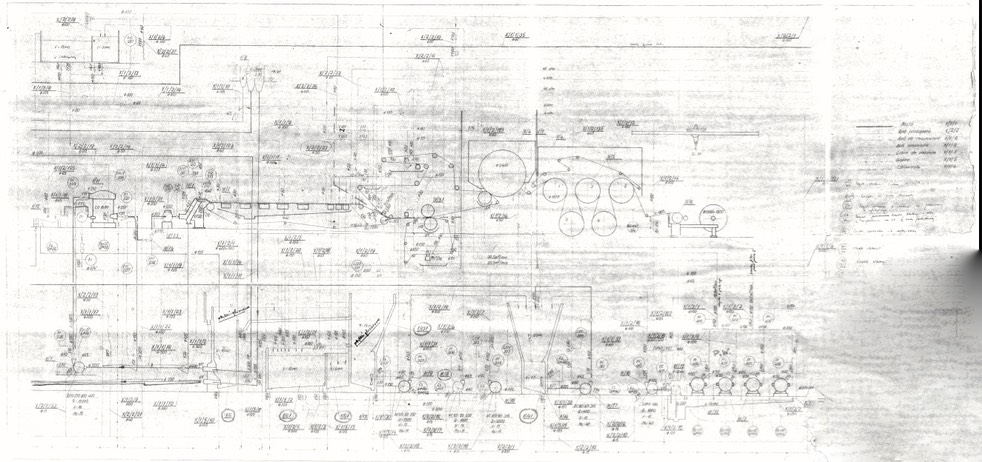

CONSTANT PART

- Head box

- Stock centrifugal pump for 1st Stage L.C.C. feeding.

- Stock centrifugal pump for 2nd Stage L.C.C. feeding.

- 1st Stage L.C.C. cleaners

- 2nd Stage L.C.C. cleaners

- Pressure screen

- Fan Pump for Paper Machine stock feeding

- Auxiliaries – pumps, agitators and propellers, water pumps, stock tanks,

Headbox

- Type : Hydraulic

- Control : Manually lip contro

- Material : the parts in contact with the stock made from stainless steel AISI 316

Wire

- Type : Converflo wire table

- Wire construction : cantilevered

- Width of wire : 2,700 mm

- Length of wire :14,800 mm

- Consisting of following components:

- Breast roll

- Length: 2 800 m

- diameter: 510 mm

- Dewatering elements:

- Foil boxes with 3 foils 7 pcs

- Hydrofoils boxes 3 pcs

- Suction boxes 3 pcs

- Couch roll

- Length: 2880mm

- diameter: 510 mm

- Turning roll 4 pcs

- Wire guiding rolls

- Manual adjustment of vacuum

- Tensioning system of the wire

- Regulator for the guiding of wire

- Couch chest with Stock agitator propellers

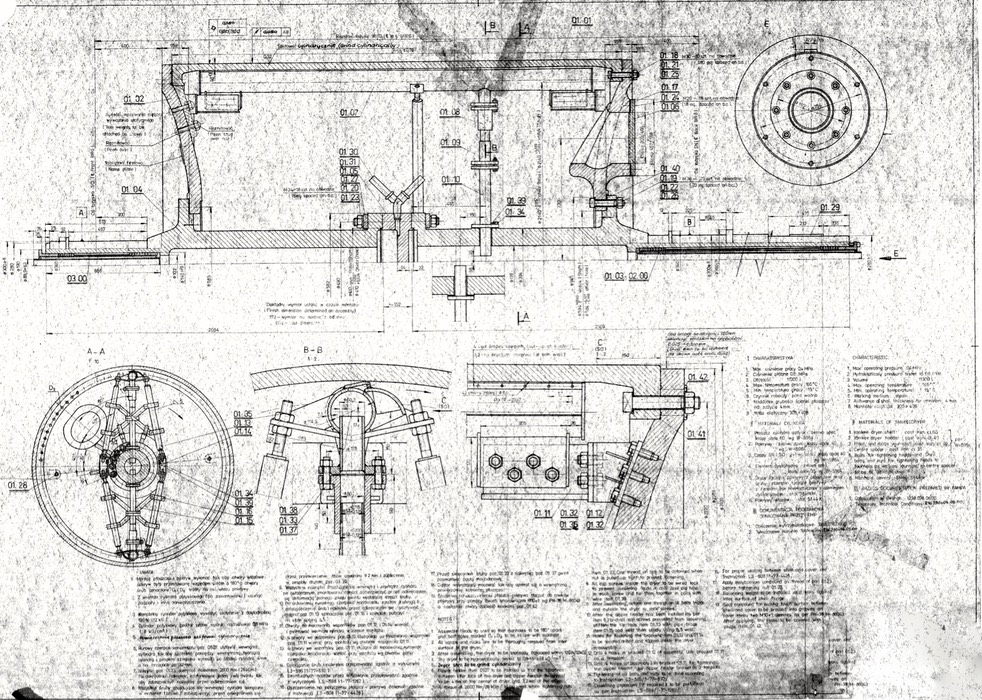

Yankee cylinder

- Diameter 2 400 mm

- Length 2.675 mm

- Material cast iron

- Pressure in the Yankee 4 bar

- Doctor blades 2 pcs

Press part

- Having a separate press and 2 pcs press rolls on the Yankee cylinder:

- Pick up box

- press suction roll TypeVenta

- nip max. press 589 N/cm

- driving by el. motor

- press roll in contact with Yankee cylinder

- blind drilled

- material steel covered with rubber

- diameter 605 mm

- max. press 80 kg/cm

- Automatic guidance of felt

- Device for tensioning the felt

- Guiding rolls for bottom felt 11 pcs

- Spiral guiding rolls 2 pcs

- Conditioning of felt

- suction box for felt 3 pcs

Hood

- Two zones hood with recuperation and air mixing

- Steam heated

- Air recuperation

- After drying group

- Drying cylinders 5 pcs

- Diameter 1500 mm

- Steam pressure 4 bars

- Doctor blades oscilating with electrical motors

- Felt tensioning and guiding system

- Hood

Steam condensate system

- Unit with pneumatic control valves

- Condensate chest

- Pumps

- WINDER

- Supplier FAMPA

- Type POPE

- Diameter of pope roll 610 mm

- Length of pope roll 2675 mm

- Doctor blade yes

- Oscillating doctor blade

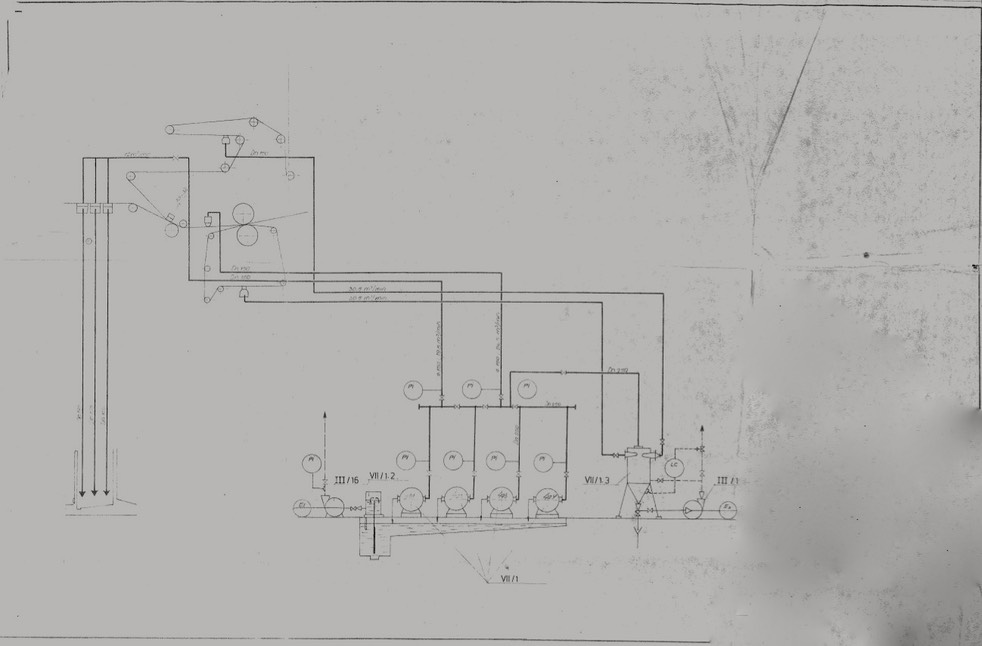

PAPER MACHINE VACUUM SYSTEM

- Water ring vacuum Pump 4 pcs

- Type WP40-S

- Capacity each of them40 m3/min

- Auxiliaries, water separators, drive systems, piping, fittings and gauges

- ELECTRICITY

- El. cabinets

- Control desks

- Drives

- Main motors with gear boxes

- couch roll

- wire turning roll

- first press bottom roll

- Second press

- Yankee cylinder

- After drying group

- pope reel

STOCK PREPARATION

- Belt conveyor :1 pcs

- Hydrapulper :1 pcs

- Stock pump from hydrapulper : 1 pcs

- Double disc refiner :1 pcs

AUXILIARIES

- Lubrication unit

- Pressure air distribution unit