Paper machine, 3,100mm, kraft, liner, 110-305gsm, extensible paper 90-100gsm, 300M/min

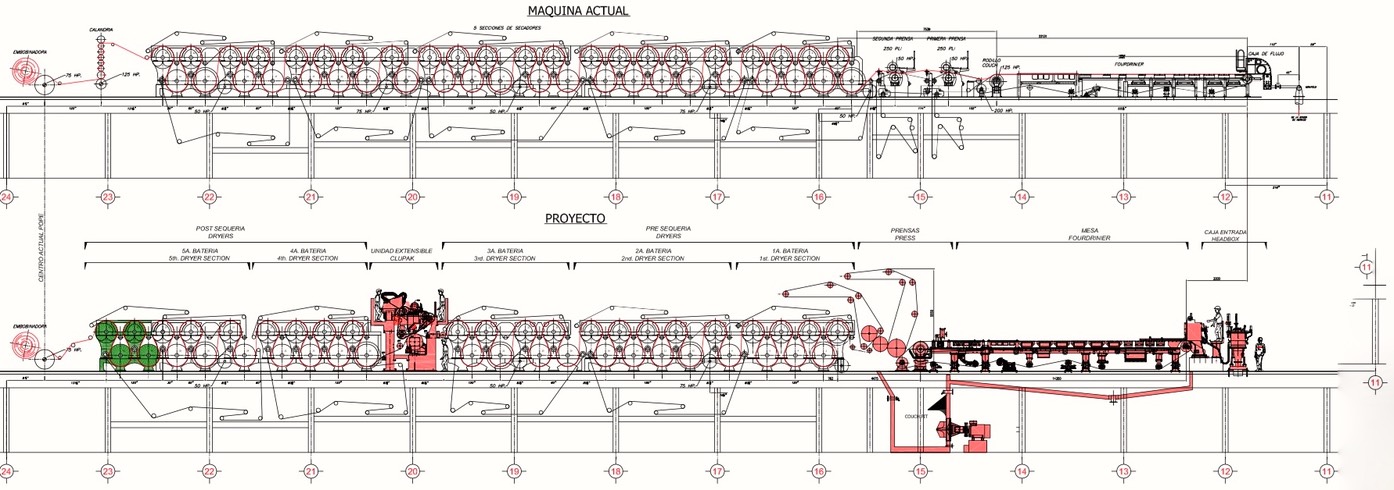

HIGHLIGHTING

- GREEN = EXISTING MATERIAL TO BE REPLACED

- RED = THE NEW REPLACED MATERIAL

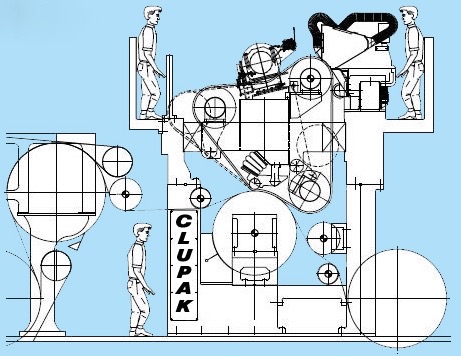

This paper machine is to be a fully rebuilt machine, especially reconfigured to be an extensible paper machine for the production of extensible paper as well as Kraft and liner. The the engineering is under the direct supervision of the world’s foremost extensible paper specialist engineers.

Why extensible paper? Because it makes a difference in packaging. It protects the products because its strength and it stretches, combining its properties to create resistance to impact, puncturing and tearing while simultaneously reducing packaging costs – Less extensible paper is needed to perform a given job. It is a high-quality packaging paper with a high market value and a competitive edge.

Extensible paper has replaced ordinary kraft paper in multiwall sacks for shipping almost every type of product. Savings in the amount of paper used per sack are usually gained in addition to improved protection and reduced sack breakage.

Extensible paper can also be coated to provide moisture protection. It can be impregnated with resin to make laminates. It can be bleached or made in colors. Its surface is well suited for printing.

The current confiration of the machine is as follows:

- Raw material: 100% OCC

- Produced papers: Medium, liner

- Grammages: 110-200 gsm

- Max width at pope: 3,149 mm

- Max working speed: 320 mpm

- Press section: 1st press 53,6 kg/cm pressure; 2nd press 53,6 kg/cm pressure

- 44 dryers 1219 mm diameter 3,44 bar pressure

- 8 roll calander

- Pope reeler, max diameter 1,524 mm

- Rewinder: max diameter 1,500 mm: max speed 800 mpm

- Closed hood