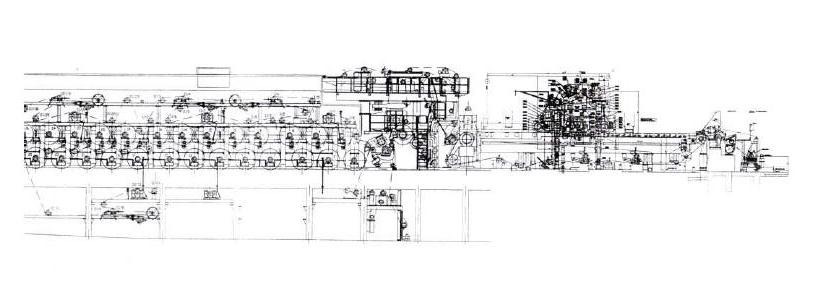

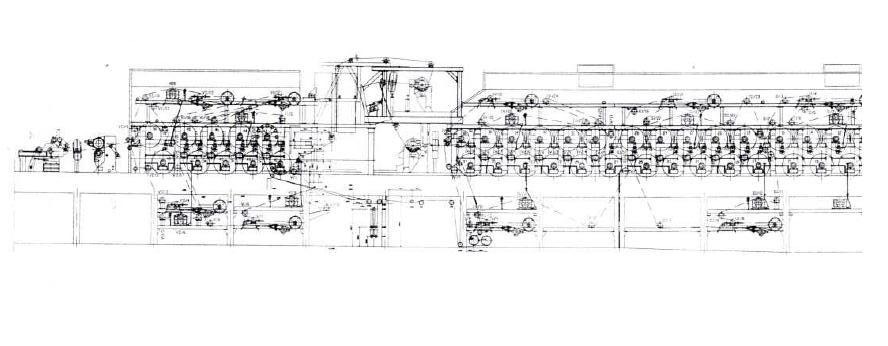

4000 mm - Paper Machine, VOITH ANDRITZ for base and Coated Paper

- Installed in 1969 / 1970 with major rebuilds in 1978, 1992, 1997 (wet end), up to year 2005 (AC drive)

- Working width: width 4000 mm at pope (80 gsm) without coating

- Width 3850 mm at pope (170gsm) with coating

- Speed: up to 1000 mpm

- Grammage range: 54 gsm base paper with coating 36gsm = 80 gsm 135 gsm base paper with coating 35gsm = 170 gsm

- Production : glossy woodfree coated papers, base paper

- Capacity : 400 tpd, 144000 tpy on base paper

Approch Flow System consisting of:

- Machine Chest

- 2 Fan Pumps

- Dekulator Clark Vikario with 1st. Step Cleaner 22 cones (total 4 step cleaner plant GL&V)

- 3 Stage Pressure Screen slotted baskets (VSi15/15 + Jylhävarra + Vsi10)

Paper Machine components:

- - Voith ModulJet Headbox WA11500, 50000 lpm with Measurex cross profil control, s/s

- - Fourdrinier by Wärtsilä 1970, rebuilt by Voith 1997 with DuoFormer D, all in s/s

- Breast Roll size Ø 720mm x

- Forming table l = 530mm

- Total 9 foils, 6 suction boxes, 2 foil boxes, 1 foil box underneath the Duoformer

- Made by IBS ceramic

- Suction Couch Roll size Ø 1000mm x

- Wire Drive and Return Roll size Ø 720mm

- Total 8 wire guide rolls with automatic wire control, rubber covered, Ø 420mm and Ø 335mm

- Wire dimensions top wire width 4460mm x

- Wire diemsnions bottom wire with 4410mm x

- - Suction Pick Up Roll Size

- - Wärtsilä Press Part, 2 Nip + 3. Press Küsters, steam box with moisture control cross profile

- Line Pressure 1st. Nip

- Line Pressure 2nd. Nip

- Line Pressure 3rd. Nip

- - Pre dryer 38 dryers with 5 bar working pressure, 2 Slalom groups + 2 conventionell dryer groups, evaporation performance 22 To H2H/h

- - Dryer group with 11 dryers with infrared dryer 3 To H2O/h evaporation performance

- - QCS with basis weight and ash content

- - 1. Coating TCT.S Blade Beloit Coating 1978, with gas fired drying Spooner 1991

- - 2. Coating TCT.S Blade Beloit Coating 1978, with gas fired driying Spooner 1991

- - Post dryer 12 dryer, 1 conventionell dryer group + 4 single driven dryers

- - 2 cooling cylinders

- - QCS for basis weight and ash content

- - Machine Calendar Wärtsilä single nip with caliper control, Küsters bottom roll 1970

- - Pope reel Wärtsilä 1970, for reels Ø 2,0m

- - IBS Spool changing system- Reel spool crane available

- - Hood, closed with heat recovery

- - Vaccum System by Sulzer Turbair Blower

- - Sectional drive by AC with frequency inverter (very recently installed) 2005

- - Automation system and controls, basis weight etc.

- Installed, out of operation since mid of 2010