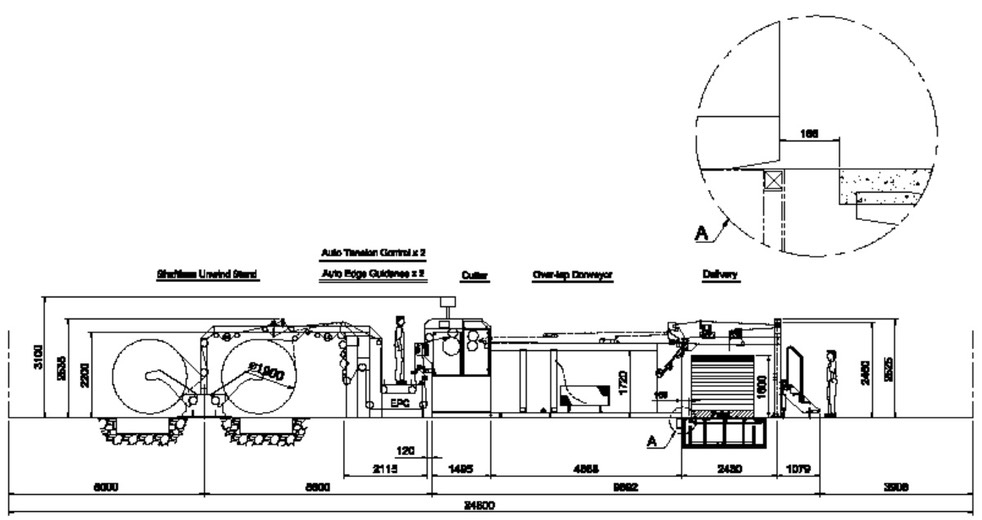

Sheet Cutter Synchrofly GMC, 1,700mm, 350m/min, to 600gsm,

I. Sheeter Specifications :

- Max. Mechanical Speed : 350 M/min

- Production Output : Practical production output is dependent on the type and characteristics of materials, sheet sizes, number of rolls, operator techniques and operating conditions.

- Trimmed Web Width : 1700 mm (max.)

- Cut-Off Capacity: 600 gsm maximum

- Cut-off length range : 400 mm (min.) – 1778 mm (max.)

- Lifting Table height : 1600 mm (including pallet)

- Sheet Length accuracy: Depending on roll quality and material characteristics, ± 0.3 mm up to 1000mm sheet length and +/- 0.05% of sheet over 1000mm sheet length for sheets from the same roll under steady running and tension conditions and correct operating procedures.

- Total Power Required : 55 KW

- Driving System : Feeder Roll and Knife Roll driven by separate motors controlled by an AC servo motor system.

- Electrical supply requirement : 380 V / 3 Phases / 50 Hz

- Air Consumption : 1538L/min @ 6 bar (working pressure 105 - 120 psi)

II. General Description :

1.- Hydraulic and Shaftless Twin Unwind Stand x 1 Set (2 positions)

- Max. Web Diameter :φ2100 mm

- Max. Web Width : 1700 mm

- Max. Web Weight : 3,200 kg / per reel

- Taper multiple size ribbed chucks : Each unwind comes standard with tapered core chucks able to handle paper core diameter : 3", 4", 5", 6", 10",11", 12"

- Air cooled disc brakes on each arm : RENOVA Air-cooled Pneumatically controlled Brakes

2.- Infeed Device

- Upper feeding roller : 1 pc

- Size : φ 240 x 1700 mm

- Material : Steel - covered with antifriction rubber

- Lower feeding roller: 1 pc

- Size : φ 450 x 1700 mm

- Material : Steel

3.- Slitter Section (TIDLAND CLASS III ) 3 Station for 2 piles out

- Slitting Knife : 1 SET (upper & lower each 1 pc)

- Trimming knife : 2 SET (upper & lower each 2 pc)

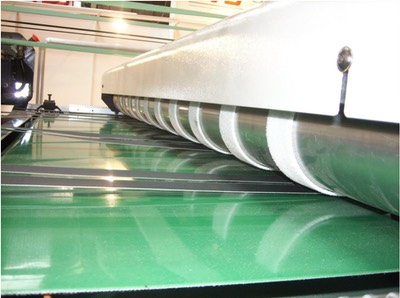

4.- Sheet Cutter

- Helical knife : 2 pc (upper and lower knife)

- Knife material : Steel

- Body: Steel

- Shaft : Steel

- Cutting length : 400 mm - 1778 mm entered by touch screen

5. - Operator-Friendly Computer Control

- By using the advance microcomputer technology to control the AC Servo Motor Synchronized with feeding speed and cutting accuracy. The touch-screen panel gives easy data entry and full information display, which includes-cut length, machine speed, job counter, pile counter, tab insertion and diagnostics.

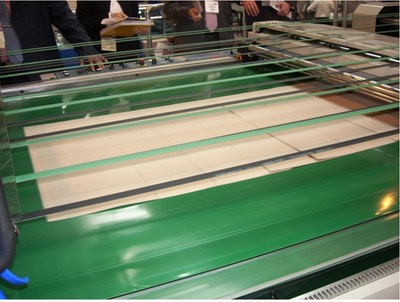

6. – Conveyor Device

- Take-way belt section

- Manual Operate Reject Gate

- Static Neutralizing Bar

- Adjustable sheet hold down vacuum system

- Sheet over-lap catch wheel assembly

- Top driving belt with easy side shift capability

- Dual speed control for sheet over lap or straight out (single file)

- Non-Stop Grid System for continuous delivery at skid change

- Top and Bottom sheet cleaner (dust vacuum system)

7. – Delivery Section

- Lifting Table Specification : 1778 (L) x 1700 (W) x 1600 (H) mm

- Max. Pile height: 1600 mm including pallet

- Max. Pile Weight : 3000 kg

- Max. Sheet length : 1778 mm (max.)

- Rear stopper : 1 SET

- Side jogger : 1 SET (left & right each)

- Top tapes over Layboy : 4 PCS

ROTARY SYNCHROFLY SHEET CUTTER GMC-TC II/1700 400 – 1778 mm cut-off range.

Main Unit :

- Sheet Cutter; the new lighter knife drums rounding around the strong stable core shaft and will ensure the better cutting quality and the speed of 350 m/min

- Shaftless twin Unwind Stand for two reels

- Auto Tension Control Unit (Load Cell Control) connected with the new innovated Renova brakes.

- Auto EPC (Edge quide positioning Control, photo Sensor+ centralizing rolls

- High Speed Tape with Overlap Section with constant vacuum system

- Delivery Section (Layboy) with Non-Stop pallet change for continuous running

Accessories :

- 2 Motorized de-curlers per reel. Small bar forpaper,bigger bar for board (dia of the bar: 20mm + 40mm)

- Slitting Station (central slitting and side trimming) (TIDLAND CLASS III )

- Trim ducting without blowers

- Dust Removal

- Static Neutralizing Bar

- Counter & 2 Tab inserters (under front jogger)

- Catwalk & handrail on both Operation and Drive Side

Standard Spare Parts :

- Cross Cutting Knives (each for upper and lower blades)

- Slitter Knife (each for top and bottom slitting blades)

- Rubber Ring of Check Roll

- Proximity Sensor

- Limit Switch

- Capacity Sensor

- Tool Kit