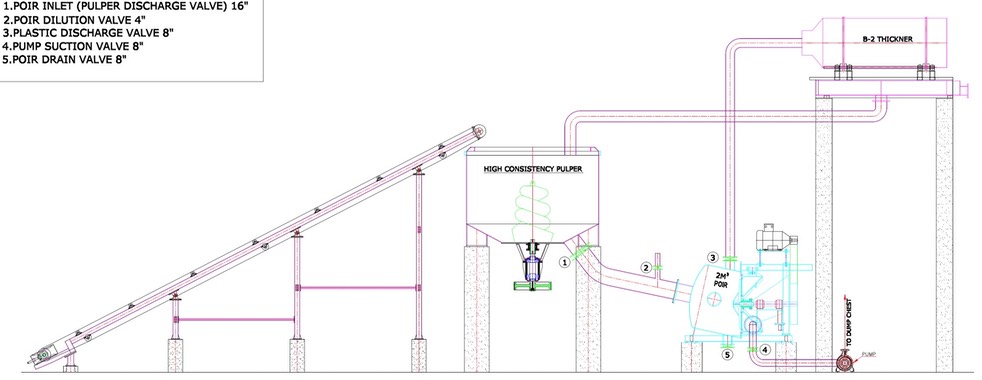

High Consistency Pulper - SMHCP

TECHNICAL SPECIFICATION EXAMPLE

Effective Slushing Volume : 20 M3

Net Volume of Vat : 22 M3

Furnish : Mixed office waste .

Slushing Consistency : 15- 18 %

Slushing temp : 60- 70 deg C ( Preferred )

Drive Motor Recommended : 140 KwX 960 rpm

Type of Drive : Belt Drive

Pulpers Vat : SS304 Complete – 10mm thk

Drive and Driven Pulleys : Included

Scope of Supply :-

• Pulper Tab fabricated in SS 304 completely welded with smooth finished surface. The vat shall be with 3 nos of MS Supports for RCC pedestals . The vat shall be complete with nozzles for stock discharge.

• Rotor : HD Screw rotor having three of equi spaced cast fabricated Helical flights 18-20 mm thick in SS304 casting. The cutting edges of the flights are duly hardened for high wear resistant properties. The rotor is dynamically balanced Rotor base plate of SS304 with bottom scraping vanes duly machined .

• Bearing Housing assembly complete with heavy duty anti-friction roller bearings Koyo Make with

thrust bearing , EN -9 shaft and deflector .

- • Drive and driven pulper pulleysPoire (4 m3 ) : 1no.

The poire will be made in S.S.304 , 8mm thick plate & base in M.S .The poire has the function to keep clean a continuous pulper. The pulp from above the screen plate of the pulper is taken into the poire . The accepts through the 12mm diameter hole screen plate taken as feed forward. After a pre-determined time, the valve, which draws flow from the pulper is closed , wash water is introduced in order to recover the fibre. After this rejects are purged out through the light reject to a drum thickener and the accept of which as usual is taken back to the pulper vat thus ensuring zero fibre loss. Subsequently, heavy rejects are discharged from the bottom.

Motor : 120 HP X 1440 RPM

Pneumatic Valves : included in our scope of supply

PLC with pneumatic Panel : included in our scope of supply. –1 No.

SS PIPE LINE COMPLETE : All Pipe line will be in SS 304

Erection Commissioning :

We supply Project Manager and technicians.

All lodging & Boarding will be in client's Account .

All the equipment & consumables will be Supplied by the client.