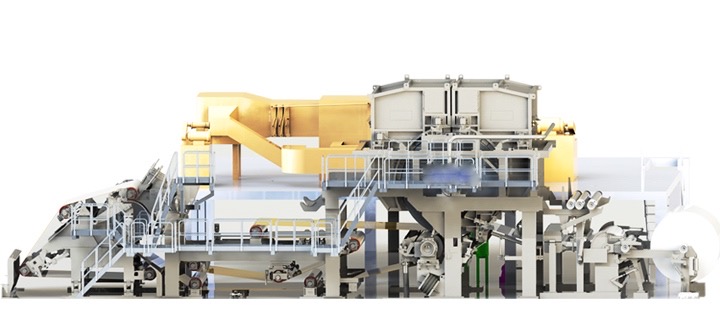

- High-speed Crescent Former Tissue Machine

Product Summary

The standard High-speed Crescent Former Tissue Machine mainly consists of hydraulic headbox, former, suction press roll, Yankee drying cylinder, high-speed hot air hood, pope reel and so on.

Technical Advantages

■ Hydraulic headbox gets excellent fiber orientation and formation so producing better tissue quality;

■ It is no need to use vacuum on CF, so there is less power consumption. And it is possible to operate with lower consistency in headbox to get better uniformity of tissue;

■ Specially designed water collection tray from the Crescent Former to reduce to the minimum the air entrainment into white water;

■ Transfer of paper from the Crescent Former to the press section is achieved by means of a single felt thus eliminating all the runnability problems created by a pick-up transfer;

■ Mist collecting system in the area of wire cleaning;

■ There is power operated position-adjustment of breast roll in order to choose the optimal jet impingement while machine is running;

■ Highest bulk value due to the large diameter press roll;

■ Efficient design of tail transfer from creping doctor to the reel performing also web stabilization;

■ The pope reel is provided with reel spools storage magazine and reel spool automatic feeding and it perform the desired jumbo roll hardness;

■ Excellent design of walkways and ladders to get access to all components of the machine.

Main Parameters

Trimmed Width: 2660~4600 mm

Basis Weight: 13~42g/m2

Operating Speed: 1200~1800m/min

- 1) The Saxon High-Speed Tissue Machine range

There are suction cylinder former and crescent former for the tissue machine and the machine mainly consists of hydraulic headbox, former, suction press roll, Yankee dryer, hot-air hood, pope reel and so on.

Our associated works has supplied 69 sets of Suction Cylinder Tissue Machines to customers with improved speed from 800m/min to 1000m/min in 2014.

Technical Advantages ■ Hydraulic headbox;

■It adopts suction cylinder former or crescent former in wire section, which brings better paper forming and high dewatering efficiency;

■It is vacuum press in press section. The dryness out of press section can reach 38~40%; ■In drying section,Yankee dryer and high-speed hot air hood bring highest dryness which ensures the high-speed running of machine; Reliable technology of steam&condensate water and heat recovery makes steam consumption per tone production reach advanced level;

■In drive section, digital AC frequency control system improves control precision, so the performance is stable and reliable.

Technical Parameter

Trimmed Width Drive Speed Basis Weight

2660~5600mm 600~2000m/min 13~42g/m2

HC-700 Suction Cylinder Tissue Machine

Technical Parameter: Trimmed Width Drive Speed

Basis Weight

2660~5600mm 700m/min 13~42g/m2

HC-1000 Suction Cylinder Tissue Machine

Technical Parameter: Trimmed Width Drive Speed

Basis Weight

2660~5600mm 1000m/min 13~42g/m2

HC-1300 Crescent Former Tissue Machine

Technical Parameter:

Trimmed Width 2660~5600mm Drive Speed 1300m/min

Basis Weight 13~42g/m2

HC-1600 Crescent Former Tissue Machine

Technical Parameter: Trimmed Width Drive Speed

Basis Weight

2660~5600mm 1600m/min 13~42g/m2