DETERGENT MANUFACTURING LINE

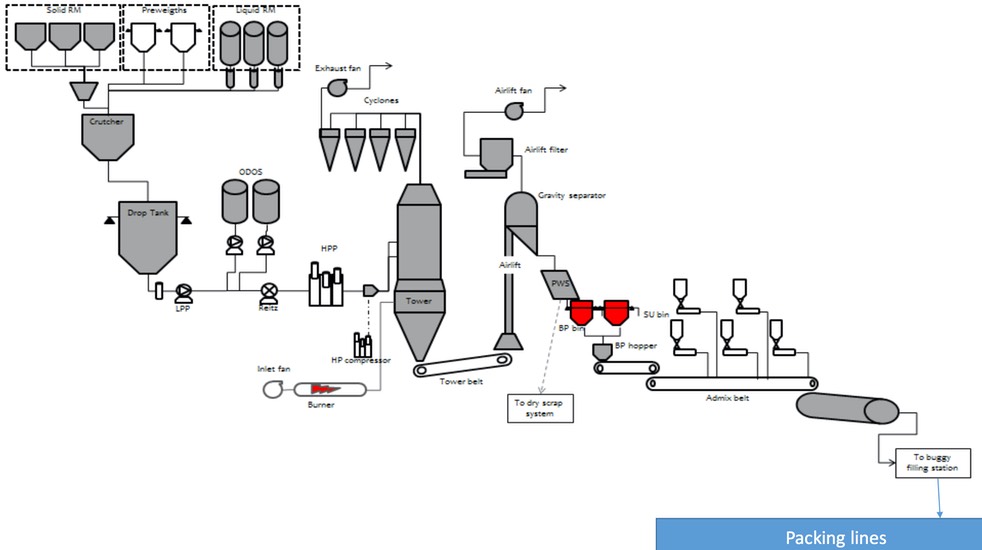

Detergent powder manufacture

Step 1 - Slurry making

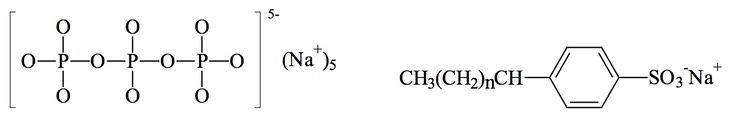

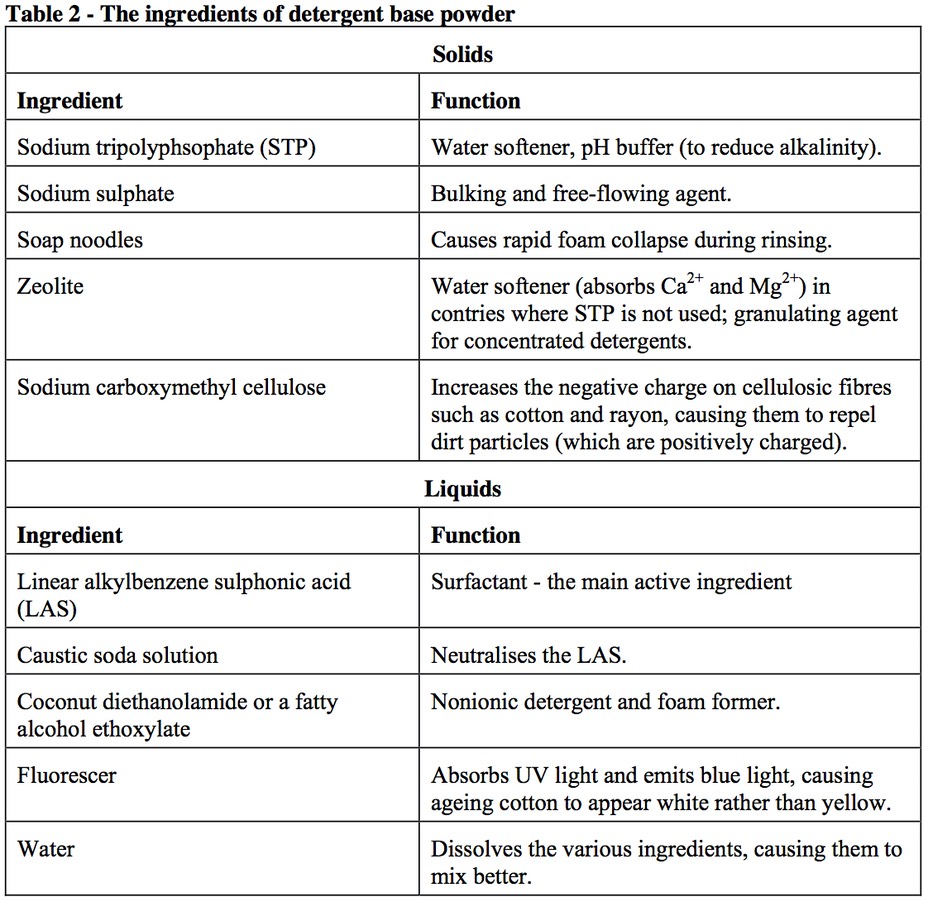

The solid and liquid raw ingredients (Table 2) are dropped into a large tank known as a slurry mixer. As the ingredients are added the mixture heats up as a result of two exothermic reactions: the hydration of sodium tripolyphosphate and the reaction between caustic soda and linear alkylbenzenesulphonic acid. The mixture is then further heated to 85oC and stirred until it forms a homogeneous slurry.

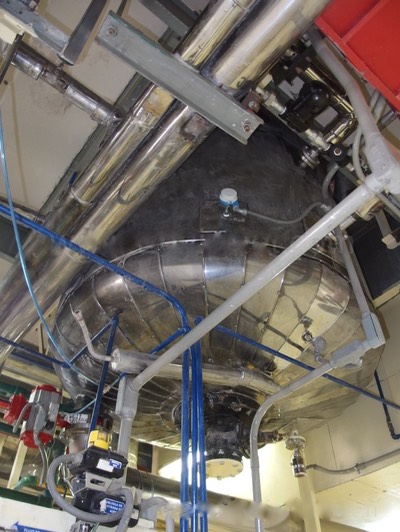

Step 2 - Spray drying

The slurry is deaerated in a vacuum chamber and then separated by an atomiser into finely divided droplets. These are sprayed into a column of air at 425oC, where they dry instantaneously. The resultant powder is known as 'base powder', and its exact treatment from this point on depends on the product being made.

Step 3 - Post dosing

Other ingredients are now added, and the air blown through the mixture in a fluidiser to mix them into a homogeneous powder. Typical ingredients are listed in Table 3.

Asset List

- Saacke Combustor CCS 150 1.7MW Furnace System

- Vacuum Pump with Control Panel

- Vacuum Pump with Control Panel

- 6000 Liter Steel Tank

- CompAir 54172 Air Compressor

- Flex Kleen 84CTWC-56Arrt.III 2293 CFM Dust Collector

- Carrier Corporation Model 30GT-025---500 25 Ton Air Cooled Chiller

- Century SA de CV Vacuum Pump with PLC Control

- 30 HP Booster Vacuum Pump

- Perfume Skid With Wilden Diaphragm Pumps And Tanks

- Atlas Copco GA45 Air Compressor with Tank

- Lot of Two Wilden Three Inch Stainless Steel Diaphragm Pumps with Control Panel

- BHA Pulse Jet 7665 CFM Dust Collector

- BHA Pulse Jet 8085 CFM Dust Collector

- BHA Pulse Jet 8085 CFM Dust Collector

- BHA Pulse Jet 8700 CFM Dust Collector

- BHA Pulse Jet 8200 CFM Dust Collector

- Pulse Jet Dust Collector #24

- BHA Pulse Jet 8600 CFM Dust Collector

- Brida Ingeniería de Proyectos S. A. Approximately 12000L Steel Agitated Mix Tank With Weigh Cells

- Neodel Pump Transfer Skid System

- Reitz Desintegrador Type R12-8-K222 Pulverizer Stainless Steel Construction

- Chopping System For Disposal Of Scrap Bags Of Powdered Detergent

- Allen Bradley Centerline Motor Control Center MCC

- Triple Super Sack And Bulk Bag Unloading System

- Mikro Pulsaire Pulse Jet 8500 CFM Dust Collector

- Mikro Pulsaire Pulse Jet 8200 CFM Dust Collector

- Atlas Copco GA90VSD 602.8 CFM Air Compressor With Tank And Air Dryer

- Perfume Unloading Skid With Wilden Diaphragm Pump And Stainless Steel Tanks

- Atlas Copco GA90VSD 633.9 CFM Air Compressor With Tank

- Lot of 6 Product Belt Conveyors

- RV Base Spray On RV Base Skid W IKA DR2000 Dispax Reactor

- American Air Filter 17000 CFM Pulse Jet Dust Collector Recently Installed Like New Condition

- URACA Pumps Type KD825 High Pressure Reciprocating Triplex Plunger Pump

Packing Lines

For packing, we have 13 packing machines, 9 UVA technology with Optima (to weight the product) and 4 masipacks.

Each of them count with their dumping spot to feed the machine and the bottom the conveyor to take out the bags to the palletizing operation. Palletizing was manual.

The final product was polyouters.

- Fischbein Model 400 Bag Filling And Sewing Closure Line

- UVA-Butler Type 350 FFS Form Fill Seal Machine With Optima CF|4 Scale Feeder For Powders 5

- MaSipack and Butler Form Fill Seal Line For Powders 2

- MaSipack and Butler Form Fill Seal Line For Powders 7

- Multiple UVA Butler Form Fill Sealers with Optima Scale Feeders, Packaging Filling Line for Powder 1

- Multiple MaSipack and Butler Form Fill Seal Line For Powders 8

- Multiple UVA Butler Form Fill Sealers with Optima Scale Feeders, Packaging Filling Line for Powders

- Multiple UVA Butler Form Fill Sealers with Optima Scale Feeders, Packaging Filling Line for Powders 4

- K Tron Admix Dry Additive System Including Multiple Feeders and Conveying Systems

- ACMA Model 753 Automatic Volumet ric Carton Filling and Case PackingLine for Detergent Powder