“NO NONSENSE MACHINES AT NO NONSENSE PRICES”

SM4025 - 220,000 Tons per Annum - Forestry assets, Sawmill & Pulp Mill

PLEASE FORWARD EXPRESSIONS OF INTEREST TO: mark@saxonmachinery.com

What’s on offer

Pulpmill: 220,000 ADMT Softwood BCTMP

History.

The pulp mill has been progressively upgraded and expanded since its original commissioning in late 1978 as a 60,000 ADMT, market Thermal Mechanical Pulp (TMP) mill manufacturing for the newsprint market. In the early 1980’s a Sodium Sulphite impregnation stage was added to convert the process to Chemi- Thermo-Mechanical-Pulp (CTMP). A Peroxide bleach plant was later added to enable the manufacture of Bleached-Chemi, Thermo-Mechanical-Pulp (BCTMP). The plant capacity was then increased to 120,000 ADMT in 1984. This expansion was undertaken using a combination of new and used plant. A new Sunds Defibrator RGP60 refiner line was added along with new screw presses ahead of the bleach plant. A second-hand flash dryer and finishing line was sourced from a Swedish TMP mill that had been shut down in 1976 after approximately 2 years of operation. The Swedish Flash Dryer dewatering machines were replaced with a new Andritz Twin Wire Press (TWP) in 1987 and a second hand Andritz TWP in 1994. In 2003 the mills production was switched to the manufacture of a short fibre pulp (still utilising Radiata Pine as the feedstock fibre) aimed at the growing Asian paperboard market. Development of refiner segment technology and the addition of an upgraded screen room and reject refiner enabled a new product line designated as AB and AB+ grades (Advance Board). The product was very well accepted and enabled production efficiencies in the form of reduced electricity consumption and increased production capacity. The mills current capacity is circa 210,000 ADMT. This latest capacity step was achieved through de-bottlenecking, equipment upgrades and process simplification, the most notable being the decommissioning of the screen room in 2019 which was enabled via continued refiner segment development.

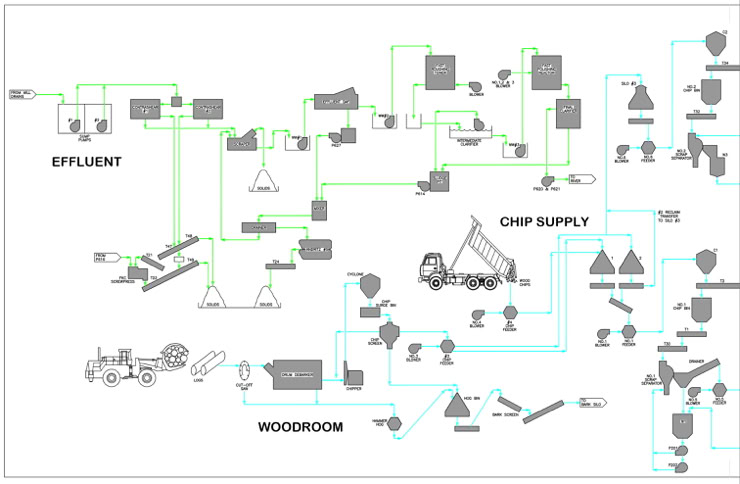

Log handling and chipping

Logging trucks weigh in across a weighbridge. The pulpmill log yard has the capacity to hold 25,000 Green Tonne Log (GTL). Further off-site storage is available within the forest (1.5km cart distance). Forest waste in the form of Bin wood has progressively increased in volume since 2017, annual input is around 70,000 GTL per year.

A new Morbark in-line drum de-barker was installed in 2021. A new Sennebogan grapple crane is used to manage log flow ex the de-barker and is also the main control point for the de-barker and chipper. The chipper itself is a Nicholson 96 inch 8-knife unit coupled with a 1 MW 16 pole motor. Both the motor and chipper have been rebuilt in last 3 years. The chip production is screened by a BM&M 12-foot x 20-foot screen installed in 2022, before being transported to 1 of the 3 chip storage piles.

The capacity of the de-barker/chipper is between 100 and 150 tonnes per hour (TPH) depending on log type and seasonal influences. Chip transportation is carried out by a Radar blower/feeder system which, depending on destination, has a lower capacity that the chipping operation. This being

1. Chip piles 1 & 2 - capacity 90 to 100 TPH.

2. Chip Silo 3 - capacity 130 TPH

Chip piles 1 and 2 have a capacity of 12,000 Green Tonne Chip (GTC) and supply the Refiner 5 RGP60 Primary Refiner. Chip Silo 3 has a capacity of 800 GTC and supplies the R7 RGP60 Primary Refiner.

Log yard mobile plant operational services run a log loader (truck unloading and de-barker feed), grapple loader (bin wood handling) and a bulldozer (chip pile management). They also provide oversize log splitting and there is a project underway to streamline the management of this and bin wood handling.

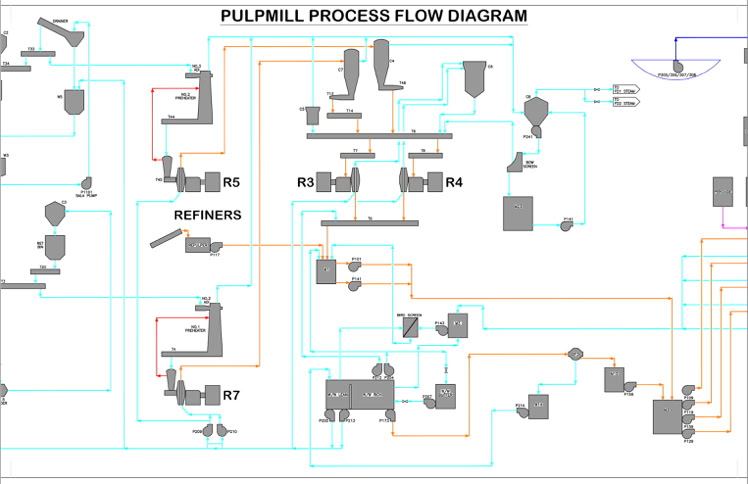

Pulp Refining

Two separate chip preparation systems are used to feed the 2 primary refiners. Chip is transported by Radar blower/feeder systems to the chip washing and chip preheating systems. The number one chip wash uses a Radar blower/feeder to transport the washed chip to the R7 preheater. Number 2 chip wash uses a chip pump to transport the chip to the R5 preheater. After preheating the chip is fed to the 2 Sunds Defibrator RGP60 flat disc refiners R5 and R7. R5 was installed new in 1982. R7 was installed in 2013 and is a rebuilt, second-hand unit. 2 spare bearing units are held on site for these machines. The primary refiners are coupled to ASEA/Stromberg 10MW synchronous drive motors. Refined pulp is blown to pressurised cyclones before being fed into secondary refiners R3 and R4. These Sunds Defibrator RLP54/58 refiners are coupled to ASEA 8.5/6.5MW synchronous motors. Two serviceable spare motors are kept. The 4 in service and 2 spare motors are of varying ages and have been overhauled as has been required.

A 1.4MW LPG fired package boiler is used for primary refiner start and shut down assistance purposes.

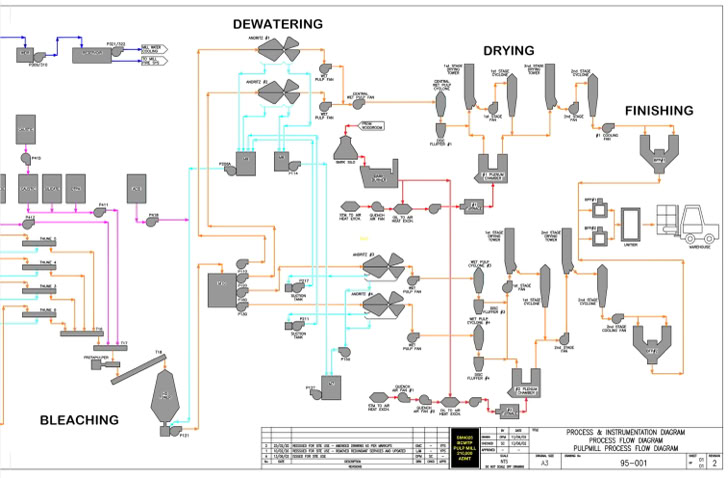

Pulp Bleaching

Refined pulp is dosed with DTPA before being held in a 40 ADMT capacity storage chest. The pulp is then pumped to the bleach plant where 4 Thune SL70 screw presses dewater the pulp to 30% consistency. The pulp is dosed with Hydrogen Peroxide, Sodium Hydroxide, Sodium Silicate and cooling water before being transferred to a Frotapulper mixer and then to a 40 ADMT high density storage tower. After around 1.5 hours the bleached pulp is removed from the tower using a screw reclaimer. Reclaimed pulp is diluted from 26% to 5% in a hydrapulper before being sent to a bleached pulp storage chest. The capacity of the bleach tower is low which results in a short residence time. The screw reclaimer also limits the consistency that the tower can be operated at. Consequently, a relatively high Peroxide dose rate of around 3.8% - 4% is required to reach a bale brightness of 75 ISO.

Pulp Drying

The mill has 2 drying lines, Flash Dryer 1 (FD1) and Flash Dryer 2 (FD2). Each dryer has 2 Andritz Twin Wire Presses ahead of the Flash Dryer themselves. FD1 Andritz machines (A1 and A2) are original equipment and are 2.0-meter-wide units with separate Double Wire and Heavy-Duty Press (HDP) sections. The machines achieve an outlet dryness of 50-51% Bone Dry (BD). The FD2 Andritz machines A3 and A4 are 2.0m and 1.6m wide machines and achieve outlet dryness of 52% and 54% respectively. Their performance advantage over A1/A2 relate to a longer length dewatering section (A3) and a twin nip HDP section (A4)

The ABN FD1 is original equipment and is of stainless-steel construction (welded sections) and has a “fan after tower” configuration. FD2 is an older design unit and is of carbon steel construction and has a “fan before tower” configuration. FD1 has a single ABD disc fluffer whereas FD2 has 2 ABN disc fluffers. Fibre scrubbers are fitted to the 4 bale forming press cyclones. These recently commissioned units are used to control emissions and to meet upcoming regulatory requirements. Both dryers are fitted with FireFly spark detection systems.

Drying Energy

Waste energy (steam) is recovered from the primary refiner pulp cyclones C4 and C7. The steam is cleaned in a scrubber before being drawn to Windsor steam to air heat exchangers fitted to FD1 and FD2. Air off temperatures are circa 60C. The performance of the heat recovery system is low compared to that achieved after its 2010 commissioning. Most of this is due to the removal of the pulp screen room (refer above) which changed the primary/secondary load split and thus reduced the primary refiner energy input.

A Eaststeel 12MW bio-waste heat plant was commissioned around 2010. The plant was originally configured to be fuelled by bark, wood fines, sawdust and WWTP sludges. A sawdust drier was added in 2014. The plant is of a vibrating grate design with an under-fire air heater, ash recovery and a 1.5MW waste heat boiler incorporated. The burner heats thermal fluid to 275C which is then pumped to a series of oil to air heat exchangers in FD1 and FD2. Air off temperatures are circa 210C.

Additional energy is supplied via 6 LPG burners. Each flash dryer is fitted with 2 x 3MW gas guns and 1 x 1.4 MW gun (commissioned 2008). This configuration allows for high energy outputs for occasions when the heat plant is down whilst also providing good turn down qualities for day-to-day operation. Fuel is supplied via a gas train comprised of a 50-tonnestorage tank, evaporators, and evaporator heating boilers. The plant was commissioned in 2001.

The Pulpmill’s LPG consumption averages 15 litres per admt during steady state operation.

Bale Forming and Finishing

The pulpmill has a Bale Forming Press (BFP) after each Flash Dryer. BFP1 is an ABN unit and is original equipment. The 600-tonne press has a capacity of 335 ADMT per day. The press hydraulic system was upgraded in 2009. The press itself was overhauled in 2018. BFP2 is a new 600 tonne Macrodyne unit which is similar in construction toe BFP1 except that it uses Valmet like screw feeders instead of ABN like feed rams. The press has been running for over 24 months but is still not at the performance levels defined by the supply agreement.

There are 2 Finishing Lines, FL1 and FL2.

FL1 is original equipment and consists of a 1,300 tonne ABN bale packing press (BPP), a Lambs Gray wrapper/folder system and 2 Oval Strapper tying machines.

FL2 consists of a 1,500 tonne Sunds BPP (ex the Swedish donor mill), a 2004 Valmet wrapper/folder line and a single Oval tying machine (2014). From this tyer on, the line is of predominantly 2014 construction. A 3-bale end tipper precedes an Oval Unityer. Each bale weighs approximately 0.25 admt with target dimensions of 600(W) x 600(H) x 900(L) mm.

Finished 18 bale packs 9 (4.5 admt) are stored in an 1,800-tonne capacity warehouse before being loaded onto rail wagons. Pulp handling in the warehouse is via clamp trucks and rail wagon shunting by a Railways owned shunter locomotive which was last overhauled in 2022.

The Railways utilise a dedicated fleet of ZWF/ZWT curtain sided rail wagons to transport the pulp to the with each wagon carrying 10 packs (45 admt). The service normally runs 5 days per week.

Control rooms and control systems

The woodroom Sennabogen log handler is effectively the woodroom control room.

The process from the chip piles to the Andritz TWP’s (excluding A3 and A4) is controlled from the “upper” control room which is located next to the pulp refiners.

The drying and finishing process is controlled from the “lower” control room which is located between the 2 finishing lines.

The heat plant has its own control room.

The mill runs a Rockwell SCADA system which was installed over a 4-year period 2018 to 2022. PI Vision is used as the process data historian. Servers for the systems (including the mill administration systems) are located in a dedicated Server Room which was commissioned in 2018. The server room is located adjacent to but separate from, the main administration building.

Electricity Supply and Distribution.

Grid exit point TNG0111 (N-1 compliant) provides high voltage supply via 3 incomers. The mill has a total of 8 switch rooms located in the main TMP building (5 MCC’s), the woodroom (1), Heat plant (1) and WWTP (1). Several transformers are located by or within these switch rooms. The WWTP has had a back-up generator installed prior to shut down, and this has subsequently been removed. 11KV power is distributed to the pulpmill water intake via overload transmission conductors. These and some additional transformers are owned and maintained independently.

Pulp Quality and Quality Management.

The mill has a laboratory which is equipped with a Valmet MAP Fibre Analyser (2021), a Pulp Expert Fibre Analyser (~2015) and a variety of standard pulp testing equipment. The Pulp Expert is used for refiner quality measurement (manual samples) while the MAP measures finished pulp on-line (pre the bleach plant).

The pulpmill produces predominantly 2 high freeness, short fibre board grade pulps, AB and AB+.

Brightness ranges are 70 – 75 ISO with most of the production being 75 ISO. Pulp freeness ranges between 350-400mls CSF. Fibre length between 1.20mm and 1.35mm. Bulk and tensile strength are circa 3.4 and 1,800 meters respectively (based on a 60-gsm hand sheet).

Sawmill : 120,000m3 Softwood per single shift

Forestry Assets : 47,494 Hectares All FSC certified.

◦ Forest 1 – Crown Forest Licence, 11,068 hec, NSA 8,600 hec

◦ Forest 2 – Freehold 3,920 hec / Leasehold 10,206, NSA 7,000 hec

◦ Forest 3 – Cutting rights / long term supply agreement – 3,900 hec, NSA 2,800 hec.

What’s included

Resource Consents (licence to Operate)

◦ Fresh Water uptake

◦ Waste Water discharge

◦ Air & Dust emissions

◦ Stormwater discharge

Intellectual Property

◦ How to make AB / AB + Softwood Pulp grades

Refiner Plate development.

Further process changes to maintain and enhance pulp quality

while lowering refining energy requirements.

◦ Product Enhancement

Grammage Reduction

Caliper / Stiffness Improvements

Fibre Supply

◦ No competition for low grade logs within supply catchment area

from external forests

◦ An established infrastructure to obtain “bin wood” from forest waste fibre flows

A “Clean Site”

◦ with respect to employment contracts / terms.

Established Logistics links

◦ Rail link direct to export port

◦ Warehousing and container packing at export port at very internationally

competitive pricing.