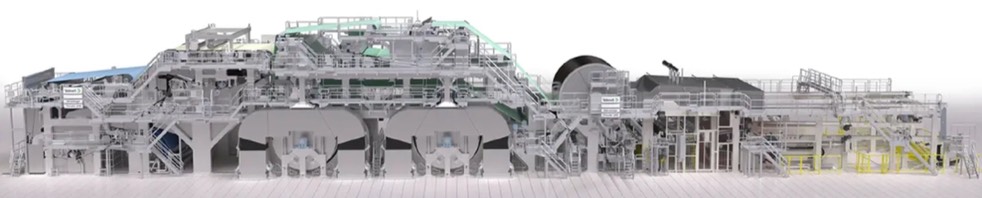

SM2740 - TAD TISSUE MACHINE 120tod

“Supreme quality with unbeatable absorbency and softness”

VALMET Advantage ThruAir Technology

Details

- Manufacturer: VALMET

- Year of construction: 1989-1990

- Raw material: Virgin cellulose bales + Broke coming from internal production

- Paper width (Original): 3630 mm (Less 40+40 mm of trim) 3550 mm net on pope reel

- Paper width (Current) : 2820 mm (Less 40+40 mm of trim). 2565 - 2740 mm net on pope reel

- Max Capacity: 120 ton/day (B.W. 30 gsm on width 3630 mm)

- Maximum drawing speeds:

- FormingSection:1400m/min

- TAD’s/Yankee:1400m/min

- PopeReel:1400m/min

- Actual production speed: 1,250 m/min, depending on paper type to be produced

- Average Overall Electric consumption: around 8 MWh

- Average Overall Gas consumption: 2000 m3/h

The machine is fully functional.

Width machine modification description – to respond to market needs.

In the dry-end section the shrinkage of the format has been obtained by occluding both sides sections of TAD honeycomb, TAD rolls and Yankee hoods. The pressure roll covering in the same way has been adapted for the new width. In the-wet end the shrinkage was obtained only by mounting narrower formation wire - 3100 mm.

![]()

Products

Paper type: BT (bath tissue) and/or KT (kitchen towel)

Reel basis weight: from 18 gsm to 30 gsm

Reel Diameter: max 2400 mm

Paper grades: HB (high bulk) caliper range from 2,7 to 4,1mm/12ply or LB (low bulk) caliper range from 2,3 to 2,7 mm/12ply

1. Stock Preparation

Automatic chain conveyors supplied by SICMA feeding Long and Short fibres to the pulpers

1 x Long Fibers line

![]()

- 1 x Short Fibers line

- 1 x broke line

- 3 x cellulose conveyors (for each pulper: long fibers, short fibers and broke one)

3 x Pulpers (Long Fibers: 46 m3; Short Fibers: 30 m3; Broke: 23 m3)

Pulper Long fibres:

- Power motor: 250 kW

- Power motor pump: 75 kW

Pulper Short fibers:

- Power motor: 200kW

- Power motor pump: 45 kW

Pulper Broke:

- Power motor: 200kW

- Power motor pump: 30 kW

- Pulping system complete of piping, valves and sensors

- 2 x Beloit disc refiners DD 4000, model J24R (power motor: 250 kW)

- 2 x de-flakers VOITH E2 (power motor: 170 kW + 200 kW)

6 x HD Cleaners (n.2 for Long Fibers + n. 2 for Short Fibers + n.2 for Broke)

5 x chest agitators of tina storage + N.3 chest agitators of tina machine

3 x fan pumps ALHSTROM ZTT 50 (power motor: 735 kW each on)

3 x pressure screens BELOIT B50 S (power motor: 90 kW each one)

1 x Fiber recovery system – BELOIT POLYDISK 2000 + N. 3 vibro screens

Vacuum system complete of piping, valves and sensors

Flow rate and consistency regulation valves supplied by BTG

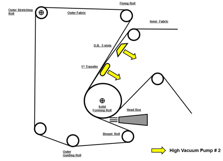

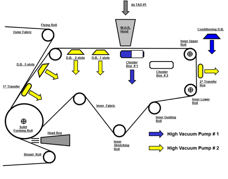

2. TAD Tissue Machine: Wet End

Forming Section

3-layer headbox: VALMET HTB-3LTwin Wires Former

Twin Wires Former

Solid Forming Roll

10 x Showers

![]()

![]()

Dewatering Section

![]()

![]()

2 x high vacuum centrifugal pumps ROOTS/DRESSER 36 SS (power motor: 1000 kW each one)

Vacuum boxes

1 x air knife powered by turbofan

3. TAD Tissue Machine: Dry End TAD Drying Section

2 x TAD cylinder (Through Air Dryer) diam.: 3658 mm, length: 4005 mm with gas burners heating by PCC (Process Combustion Corporation)

![]()

![]()

2 x Fan for of TAD system, flow 424000 m3/h, power motor: 1350 kW each

4 x TAD Hoods by Flakt Ross with gas burners

![]()

Yankee Drying Section

1 x Yankee Dryer, diam.: 3600 mm, length: 4200 mm, operating pressure: 7,5 bar; max pressure:20,68 bar, T max: 205 °C

1 x Yankee coating system

2 x Yankee Hoods by Flakt Ross with gas burners (power motor centrifugal fan: 250 kW)

![]()

4. TAD Tissue Machine: Reeling Section

1 x Pope Reel

1 x Evacuation system of jumbo reels from pope

N. 1 Shaft puller system + crane for core reels movement

N.1 Dust removal system installed at the machine wet end & Pope reel section

N.1 Dust removal system installed at the machine wet end & Pope reel section

![]()

5. Additional details

All drive motors and control cabinets for Tissue machine are supplied by ABB

DSC and QCS supplied by ABB.

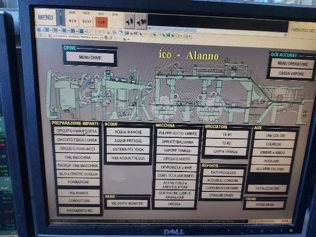

QCS scanner equipped with radioactive source sensor to measure BW & moisture in line. Control room

![]()

Complete water system (motors, piping, etc.)

Most of the motors are powered in medium voltage, 6000 Volt and low voltage 380 Volt 50 Hz

Spare parts available (motors, rolls, wire formers, etc.)

- All the available spare parts will be included in the scope of supply

- All the available machine wires (3,100 mm) will be sold at purchasing cost