🖥 - Tissue Machine, Crescent Former, 2,300mm trim at pope, circa 40-45tpd

This excellent condition Tissue machine producing 11,000 tpa to 14,000 tpa of Tissue at grammages of 13 to 40 gsm will be available from 1st January 2019.

For further information please complete and sign the Confidentiality Agreement (click here) and return to mark@saxonmachinery.com

DETAILS OF TISSUE MACHINE

Key Details

- Machine is still in operation as at September 2018

- Crescent former design with 3.6m diameter Yankee dryer

- Tissue Width at Reel 2,300 mm

- Jumbo reel diameter 2,000 mm

- Design Speed 1,350 mpm

- Grammage range 13 gsm to 40 gsm

- Production rate 11,000 – 14,000 tonnes per year

- Tissue machine installed circa late 1980’s

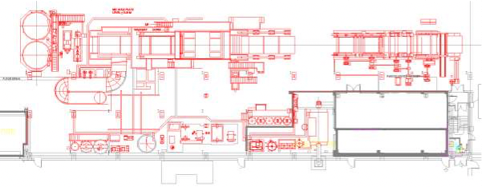

Figure 1 Tissue Machine

Machine configuration

- Hydraulic Headbox (2340 mm slice width)

- Crescent former

- Single press

- Yankee dryer 3597mm diameter x 2489mm face width

- Yankee steam pressure - 125 psig (100 psig safe working pressure)

- Yankee root shell thickness – 2.033”

- Infinikote full face YD coating applied in 2001

- Includes off-line Rewinder

Rebuilds:

- Wet End Hood (approx. 2013)

- Calender on RW (approx. 2015)

- New DCS (approx. 2016)

TISSUE MACHINE & OTHER EQUIPMENT AVAILABLE FOR SALE

The main items of existing equipment available are:

- Crescent forming section and headbox including sole plates.

- Forming roll drive, gearbox & motor.

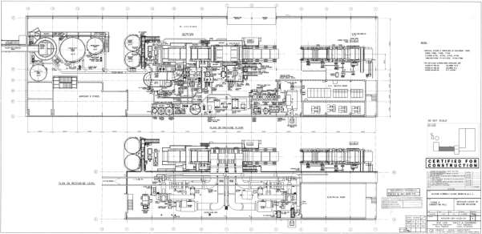

Figure 2 Existing Crescent former section

- Fabric section, frame work, drives, gearboxes, motors including sole plates.

- Felt section, frame work, drives, gearboxes & motors including sole plates.

- Yankee dryer including framework, platforming, drives, gearboxes etc.

Figure 3 Existing Yankee section

- Yankee hood air system including fans, burner systems, dampers, supports, lagging and

- cladding.

- Yankee steam system.

- Pressure roll including sole plates.

- Pressure roll drive, gearbox & motor.

- Pressure roll control panel.

- Press hydraulic unit.

- Reel section including framing, soleplates, platforming, drives, gearboxes

- etc.

- QCS Scanner frame and panel (radiation source will be removed by mill).

- Dust system including scrubber, fan, ducting and hoods.

- Vacuum system including pumps, motors, separators and piping.

- Ancillary equipment on the drive side of the machine.

- Lubrication systems.

- Hydraulic systems Winder section including framework, platforming, drives,

- gearboxes etc.

Figure 4 Existing Winder section .

OTHER PROCESS PLANT AVAILABLE FOR SALE

The main items of existing equipment available are:

- Blend chest.

- Blend chest agitator.

- Blend chest pump.

- Deflaker.

- Double disc refiner.

- Double disc refiner oil unit.

- Machine chest.

- Machine chest agitator.

- Machine stock pump.

- Stuffbox.

- Silo tank and flume.

- Fan pump.

- Fan pump drive.

- Pressure screen.

- Vibrating screen.

- LD cleaner.

- Mixwell tank.

- Mixwell pump.

- Wire pit pump.

- Consistency dilution pump.

Figure 5 Existing Blend chest and Machine chest

Figure 6 Existing fan pump and pressure screen

- Booster pump.

- Effluent sump pump No.1.

- Effluent sump pump No.2.

- WW filter.

- WW filter accept tank.

- Filter shower pump.

- Fabric shower pump.

- FW tank.

- Felt shower pump.

- Seal water pump.

- HP pump No.1.

- HP pump No.2.

- Vacuum separator.

- Starch additive system (including Kymene, Starch cooking and Starch

holding tanks). - Yankee chemical additive system.

- Chemical additive system No.1.

- Vacuum pump No.1.

- Vacuum pump No.2.

- Vacuum pit pump.

- Reel drum vacuum blower No.1.

- Reel drum vacuum blower No.2.

- Steam boiler complete with associated chemical systems.

Drawings & Documentation

An extensive package of equipment drawings, piping & layout drawings, and many photographs are available to help the buyer reinstall the plant