SM0852 :2,200mm PAPER MACHINE 2,200MM TRIM, BMB 1975, rebuilt 2002 & 2004 by Voith

PAPER MACHINE

Approach flow

Head box with CD dilution basis weight

profile control

Fourdrinier machine with dandy roll

Press section with 3 hydraulic presses

Drying section

Size press

Post drying section,

2 cooling cylinders

On-line calender (4 steel rolls)

Pop-reel

QCS (2 frames)

DCS

STOCK PREPARATION

DISPERSING AND REPULPING: 3 pulpers

REFINING: 2 refining lines with 4 double disk refiners

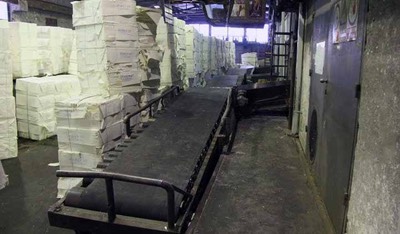

FINISHING

2 winders

2 sheeters

Cut-size sheeting and wrapping line

Reem wrapping line

Palette straping and wraping line

LIST OF BASIC COMPONENTS

Paper machine PM4

Winder BMB

Winder Goebel

Sheeter Bielomatik No. 4

Sheeter Bielomatik No. 5

Cut size sheeting and wrapping line Bielomatic

Guillotine cutting machine Polar

Ream wrapping line Lamb

Palette straping and wraping line Reker

Laboratory with instruments for paper testing

Paper machine PM4

Made by Neyrpic

Year 1975

Major Rebuild 2002 Voith,

2004 Voith

Paper Grades copy, office paper,

specialty papers

Working Width 2200 mm on reel

Slice Width 2506 mm

Design Width 2600 mm

Basis Weight 50 – 220 g/m2

Operating Speed 300 - 450 m/min

Capacity 115 T/day/80 g/m2

Voltage 400 V and 6 kV

Frequency 50 Hz

Drive Side left in paper run direction

Spare Parts included as far as available

Technical Documentation included as far as available

Condition machine was fully operational when

shut down in 03/2012

Complete approach flow system for fourdrinier,

3-stage cleaning plant,

2 stage screening system,

2 fan pumps,

main fan pump Andritz frequency controlled and relating tanks,

pulsation damper,

dilution water line, pipes, pumps, valves

instrumentation from the machine chest to the headbox

Voith MasterJet F/B Headbox

ModuleJet dilution technology for CD basis weight profile control

Type MasterJet II

F/B-25/4-MJ-H-SC-3L

Pond Width 2506 mm

Headbox Size 25/4

Number of Rods (lip) 14

Module Spacing 64 mm

Number of Modules for CD Control 39

Construction Speed 1000 m/min

Working Speed 1. phase 460 m/min

Working Speed Final 800 m/min

Throughput onto Wire (after rebuild) Max. 18.000 l/min

Throughput onto Wire (future) Max. 29.000 l/min

Scope of equipment

Fourdrinier wire part made of steel framing with wire couch roll, wire drive roll, wire suction roll, guide rolls, showers, dewatering elements, suction boxes, stretcher, wire guiding system, valves and instruments

Dandy rolls diameter 1200mm and 800 mm, water collection roll after dandy Voith DuoShake

Press part with suction pick up roll also isostack press, followed by 2nd press with felt on bottom side and 3rd offset press, felts conditioning equipment, hydraulic unit, steel framing, stretchers for felts and felt guiding

Main drying section with 24 cast-iron cylinders 1500 mm diameter, designed for 3 Bar steam pressure, complete steam and condensate system, all fabric runs and fabric controls, closed hood with controllable vapour extraction and fresh air ventilation, pocket ventilation, heat recovery system, electrically operated lifting door, steam and condensate system and ventilation controlled by DCS

Impregnation part with size press

Rope system press section, drying section, impregnation part, calander and pope reel

Post drying section with 8 cast-iron cylinders 1500 mm diameter, designed for 3 Bar steam pressure, complete steam and condensate system, all fabric runs and fabric controls, closed hood with controllable vapour extraction and fresh air ventilation, pocket ventilation, electrically operated lifting door, steam and condensate system and ventilation controlled by DCS

Cooling cylinders at the end of post drying section

Three nip calander with four steel rolls, one is Kuesters

Pope reel

Complete wet broke system with broke pulper, pump, valves, instruments and controls

Complete dry broke system with broke pulper, pumps, tanks, valves and instrumentation

Complete vacuum system with 6 Nash vacuum pumps and one vacuum fan

Polydisc filter

Central oil lubrication system

Metso QCS system with 2 frames - before impregnation and before reel with 2 basis weight sensors,

2 moisture sensors, ash sensor, caliper sensor, color sensor and basis weight, moisture, ash controls

Alsthom DC multi – motor drive system including all motors and controls - MDD

Telemeqniue motor control cabinets – MCC

Metso distributed control system – DCS

Compressor station - 2 Kaeser compressors, Kaeser air dryer, Kaeser control

Cranes in production hall with lifting capacity 16 tons and 8 tons

Power distributing system with 2 Siemens dry transformers and 3 Union oil transformers and all switch gears.

Power distributing system is controlled by PLC.

Spare Parts included as far as available

Technical Documentation included as far as available

Condition machine was fully operational when shut down in 03/2012

Pulpers

Made by Jones

Type Shark 44”

model horizontal

Year 1975

Volume 23 m3

Capacity 140 T/day

Motor 200 kW, 980 rpm

Voltage 6 kV

Frequency 50 Hz

Scope of Equipment pulper,

motor,

valves,

conveyors,

electro cabinet

Spare Parts included as far as

available

Technical documentation included as far as

available

Condition was fully operational

When shut down

in 03/2012

Refining lines

Made by Jones

Type DD 20” - 4 refiners

Year 1975

Flow 300 - 800 l/min

Consistency 4,5 %

Motor 200 kW, 980 rpm

Voltage 6 kV

Frequency 50 Hz

Scope of Equipment two refining lines for

separate short and long fiber

refining, refiners, motors,

pumps, pipes, valves,

instrumentation, tanks,

electro cabinet

Spare Parts included as far as available

Technical Documentation included as far as available

Condition fully operational when shut

down in 03/2012

Winder BMB

Made by NEYRPIC - BMB

Type Two drum winder

Year 1976

Paper Basis weight 50 – 300g/m2

Sheet Width Max 2200 mm

Operation speed 1200 m/min

Type of Unwind Stand reel spool

Max Unwind Diameter 1800 mm

Max Rewind Diameter 1500 mm

No. of Slitting Knives 9

Motor 35 kW (DC motors - 2 peaces)

Voltage 400 V

Frequency 50 Hz

Scope of Equipment Complete as installed with

all drives and controls,

electro cabinet and hall crane

lifting capacity 8T

Spare parts included as far as available

Technical Documentation included as far as available

Condition machine was fully operational when

shut down in 03/2012

Winder GOEBEL

Manufacturer Goebel

Type Optislit m

Year 1988

Paper basis weight range 50 – 400 g/m 2

No. of Stations 3

Sheet Width Max 2200 mm

Operation speed 1500 m/min

Type of Unwind Stand reel spool

Max Unwind Diameter 1800 mm

Max Rewind Diameter 1300 mm

No of Slitting Knives 9

Drive 38 kW (DC motor)

Hydraulic drive on winding heads

Voltage 400 V

Frequency 50 Hz

Scope of Equipment Complete as installed with all drives

and controls, electro cabinet and hall crane

with lifting capacity of 8T

Spare Parts included as far as available

Technical Documentation included as far as available

Condition machine was fully operational when shut down

in 03/2012

Made by Bielomatik

Type P 380/78

Year 1976

Paper Grade board, papers

Max Knife Load 600 g/m2

Sheet Width Max 1450 mm

Sheet Width Min 550 mm

Format Length Max 1600 mm

Format Length Min 415 mm

Longitudinal Slitting Knives 3

Trim Removing System

Auto Format Change

Max Cut Number 400 cut/min

(depending on sheet length)

Operating Speed 400 m/min

No. of Unwinds 2

Core Diameter 70/75/120/150 mm

Max Unwind Diameter 1500 mm

Max Reel Weight 2500 kg

Sheet Counting

Ream Insert Units 2 peaces

Motor 19,5 kW (DC motor)

Voltage 400 V

Frequency 50 Hz

Scope of Equipment complete as installed from

unwind stand to stacker with

all drives and controls, electro cabinet, web inspection system

Spare Parts included as far as available

Technical Documentation included as far as available

Condition machine was fully operational when shut down in 03/2012

Made by Bielomatik

Type P 785/22 VGL-S

Year 1981

Paper Grade board, papers

Max Mechanical Knife Load 1000 g/m2

Max Operating Knife Load 600 g/m2

Cutting Tolerance ± 0,5 mm format length

less than 1000 mm

Cutting Tolerance ± 0,5 % format length

longer than 1000 mm

Longitudinal Slitting Knives 3

Trim Removing

Sheet Width Max 1450 mm

Sheet Width Min 550 mm

Format Length Max 1600 mm

Format Length Min 415 mm

Auto Format Change

Max Cut Number 400 cut/min

(depending on sheet length)

Max Operating Speed 300 m/min

No. of Unwinds 2 double pick up unwind stands

Core Diameter 70/120 mm

Max Unwind Diameter 1500 mm

Max Reel Weight 2500 kg

Sheet Counting

Ream Insert Units 2 peaces

Motor 45 kW (DC motor)

Voltage 400 V

Frequency 50 Hz

Scope of Equipment Complete as installed from

unwind stand

to stacker with all drives and

controls, electro cabinet,

web inspection system

Spare parts included as far as available

Technical Documentation included as far as available

Condition machine was fully operational when shut down in 03/2012

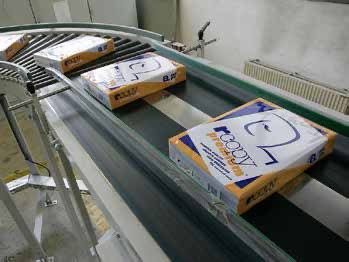

Cut size sheeting and wrapping line Bielomatik

Made by Bielomatik

Year 1999

Rebuild 2007

Voltage 400 V

Frequency 50 Hz

Drive side Left in paper run direction

Spare Parts included as far as available

Technical Documentation included as far as available

Condition line was fully operational when shut

down in 03/2012

Unwind stands with hydraulic unit – 5 stands

- roll diameter max 1524 mm

- roll diameter min 550 mm

- paper width max 1200 mm

- roll weight 2500 kg

- self expanding chucks

- manual roll change

Overhead bridge system for 5 sheets

Web guiding system for 5 sheets

Motorized decurling devicefor 5 sheets

Slitting unit

- 6 longitudinal knives

- knife load 400 g/m2

- cutting tolerance ± 0,1 mm

Trim system with vacuum cleaner with 6 nozzles

- trim fan capacity 2500 m3

- pipe diameter 200 mm

- pipe length max 50 m

- height difference 4 mZE SHEETING AND WRAPPING LINE BIELOMATIK

Synchro knife block for sheet length 297 mm

- number of cuts max 1200/min

- format length 297 mm

- construction knife load 600 g/m2

- operating knife load 500 g/m2

- cutting tolerance 0,1 mm

Overlapping unit

Collecting unit for five reams and transport to right

- ream height max 70 mm

- ream heightmin 15 mm

- number of sheets max 500

- number of sheets min 200

- number of reams max 5

- number of reams min 2

Transfer to turning station

Turning station

- size max 470 x 470 mm

- size min 150 x 200 mm

- capacity up to 2,5 kg 75 reams/min

- ream height max 130 mm

Infeed for synchronization

Ream wrapping machineCSW 75

- No. of cycles A4 70 reams/min

- No. of cycles A3 35 reams/min

- Ream height max 127 mm

- Paper quality ream min 60 g/m2

- Unwind unit for wrapping paper

or clear wrap with decurling device

- Nordson hotmelt gluing device Vista 3500

- Automatic lubrication plant

Ream roller conveyor

Ream conveyor belt

Pago model 6/2 label dispenser with thermo printer

With table for labeling device

Turning belt conveyor

Ream stacking station with accumulator

- 8 reams A4 per raw

- 5 layers

- capacity A4 100 reams/min

Outfeed belt

Stack turning station

Cartonizer CSC 100

- formed cartons dimensions max 458 x 340 x 325 mm

- formed cartons dimensions max 294 x 220 x 195 mm

- size range of reams max 440 x 330 x 80 mm

- size range of reams max 210 x 210 x 35 mm

- production speed A4 18 cartons/min 5 reams/carton

13 cartons/min 10 reams/carton

- infeed conveyor for connection with upstream equipment

- body forming station

- lid forming station

- body and lid blank station

- Nordson hotmelt gluing device Vista 3500

- Automatic lubrication plant

Carton roller conveyor

Carton roller conveyor 90°

Sato label device for cartons

- Type M-8485Se

Mosca straper

- Type RO-TRP-4

- Capacity single strap 20 car tons/min

- Capacity double strap 10 cartons/min

Conveyors

Robot Kuka

- Robot type KR125L100/2

- Electro cabinet type KR C2

- Capacity A4 20 cartons/min

- Capacity A3 10 cartons/min

Palettes magazine

Roller conveyors for palettes

Robopac wrapping machine

Finishing department

Paper from sheeters is transported to finishing department. There is final paper control, paper can be

guillotine trimmed or cut into smaller sizes on Polar Guillotine cutting machine, ream wrapped on Lamb

half automatic ream wrapping machine, strapped and wrapped with folio on Reker wrapping line with

oven and transported to warehouse.

Spare Parts included as far as available

Technical Documentation included as far as available

C ondition wasfully operational when shut down in 03/2012

POLAR 155 EMC Monitor LAMB REAM WRAPPING MACHINE REKER WRAPPING LINE WITH OVEN

Laboratoryescription of Equipment and Manufacturer Scope

1. Precision Glass Ruler with 1/10 mm scale division Hirlinger AG Precise measurement dimension

2. Spectrophotometer BCM-M Frank-PTI Paper Color and opacity

3. L&W Micrometer D2/50, Type 2-2-2 Thickness

4. Precise balance Sartorius L 420 P GSM and Substance

5.1 L&W Tensile tester Alwethron TH1 Tensile Strength

5.2 Folding tester Karl Frank 13955-digitalized Folding Endurance

6. Folding tester Karl Frank 955-analog Folding Endurance

7. Tearing tester Elmendorf L&W 125 Tearing Resistance

8. Roughness and porosity tester Bendtsen, Frank PTI, Type P60410 Porosity and roughness

9. Roughness and porosity tester Bendtsen, Karl Frank, Type 33813 Porosity and roughness

10. Smoothness-Softness-Porosity tester W.& L.E. Gurley, NY, Type TW1356 Smoothness, Softness, Porosity Gurley

11. Crumpling tester Reprotest B.V., Amsterdam, Type 86.422.C.49 Preparation of crumpled specimens

8. Roughness and porosity tester Bendtsen, Frank PTI, Type P60410 Porosity and roughness

9. Roughness and porosity tester Bendtsen, Karl Frank, Type 33813 Porosity and roughness

10. Smoothness-Softness-Porosity tester W.& L.E. Gurley, NY, Type TW1356 Smoothness, Softness, Porosity Gurley

11. Crumpling tester Reprotest B.V., Amsterdam, Type 86.422.C.49 Preparation of crumpled specimens

12. Smoothness tester Bekk, Karl Frank, Type 33512 Smoothness

13. Refract meter, Carl Zeiss Jena Angle of refraction

14. Laboratory oven, Elektrosanitarij LPH Ash Content

15. pH meter Mettler Toledo Type 220 Paper pH

16. Laboratory drying chamber, Instrumentaria Zagreb, Type ST-01/02 Moisture

17. Burst tester BURST-O-MATIC L&W, Type 14/1 Bursting resistance

18. UV lamp, Fluotest Heraeus, Germany Fluorescence

19. Kajaani FS300, Metso Fiber length

20. Water absorption tester L&W, Type 146 Cobb test

21. Magnetic Signal Tester QCD 220 2208 Magnetic signal